With the rapid development of solar panels and the continuous innovation of their technology, the products are gradually developing towards beauty, fashion, high reliability and high performance. Adhesives are also adopted by more and more manufacturers. The technical and economic benefits obtained by the application of adhesives have attracted great attention and attention from the solar panel industry.

Adhesive properties

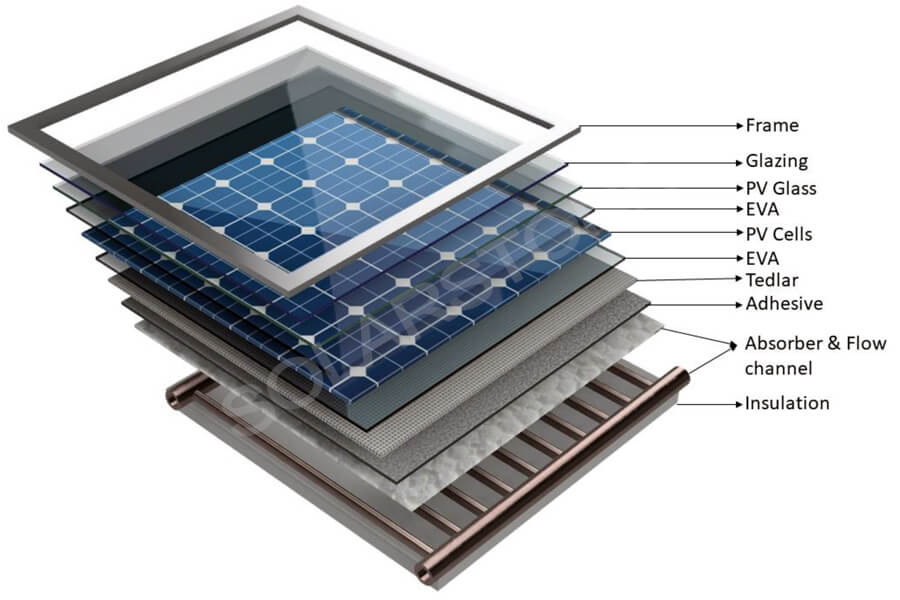

The main function of adhesive is to connect the bonded materials together. After the solar cell is laminated with EVA, back plate and glass, it needs to be bonded with aluminum alloy frame with adhesive. Bonding solar cell panel needs to bear self weight, wind load, snow, hail and other mechanical loads. Therefore, the adhesive should have sufficient bonding strength to meet the requirements of solar cell panel bearing mechanical load.

Optical performance

Unprotected solar cells placed in the natural environment will affect their stability, reliability and service life. They must be encapsulated and isolated from the external environment to ensure their long-term stable power generation.

The adhesive used for solar cell packaging shall have high light transmittance, and the refractive index of the adhesive used for external packaging shall also match that of glass and solar cells, Ensure light absorption efficiency. EVA material is widely used in solar panel packaging process, and its optical properties can meet the current packaging process requirements.

Sealing performance

Sealing is actually to prevent the penetration of destructive liquids and gases. In the process of solar panel assembly, the requirements for the tightness of the adhesive are extremely strict. The adhesive itself must have no pores and bubbles, and the cured adhesive should be continuous, homogeneous and dense in structure and have the performance of blocking the transmission of media.

The bonding interface performance of the adhesive to the material can prevent the penetration of liquid and gas, and also has a direct impact on the sealing reliability. The sealing performance of adhesive is an extremely key index affecting the reliability and stability of solar panels.

Adhesion to different materials

The main materials for solar panel manufacturing, such as glass, aluminum alloy frame, back plate and junction box, have great differences in surface state and material due to different suppliers, and the actual bonding effects of various brands of adhesives are also very different. Sufficient bonding tests shall be conducted for any change of materials to verify the applicability and compliance of the results.

Deformation capacity

During the use of solar panels, certain deformation and relative displacement will occur between components due to external force loads such as wind load, snow, hail and temperature changes. Therefore, the adhesive should have good ability to absorb deformation to adjust the external force deformation ability of the bonded object and prevent damage to solar panels in the service environment.

If the solar panel is used in alternating temperature, the adhesive can carry out micro expansion or deformation between different materials. Through the process of micro expansion or deformation, the thermal expansion difference between different materials can be effectively adjusted, so as to achieve the purpose of firm bonding.

Aging resistance

Solar panel manufacturers require the service life of solar panels to reach 25 years. In the long process of use, the performance of the bonding part will gradually decline under the action of light, heat, water, oxygen (ozone), salts and microorganisms.

This process is called aging. After the aging process, the physical, mechanical, electrical and optical properties of the adhesive used for solar panel assembly must be above a certain index, so as to ensure that the solar panel can work stably, reliably and safely within the promised service life.

Compatibility

Various adhesives used for solar panel assembly shall have good compatibility, that is, the adhesive shall not have adverse reactions with all materials on the solar panel during or after curing, such as colloid yellowing, EVA yellowing, terminal corrosion and other negative reactions.

Electrical insulation performance

Electrical insulation performance is an important index of adhesive used for live components in solar panels, especially for solar panels connected to power grid. The insulation performance of adhesive has become an important issue related to personal safety. This performance is usually measured by volume resistivity and breakdown voltage.