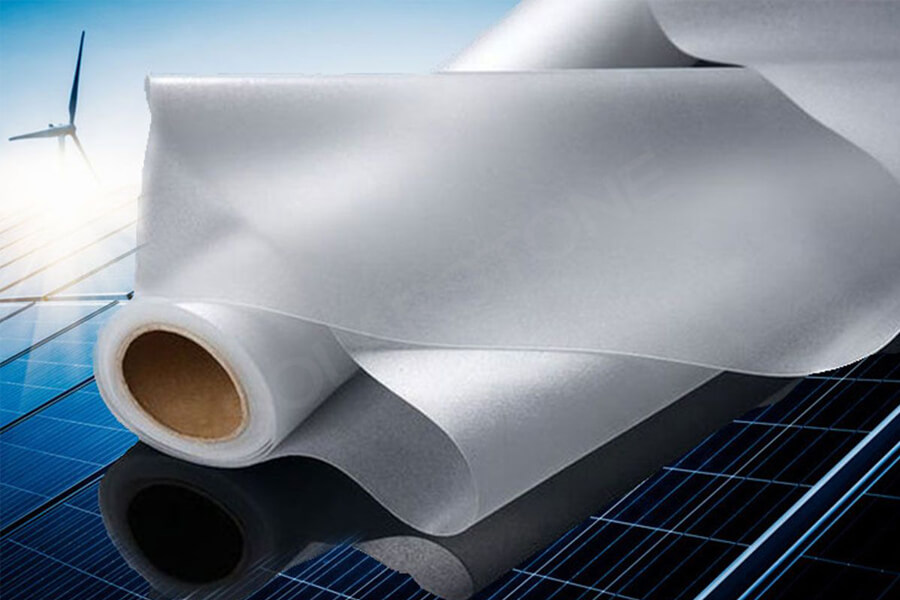

As friends who know about solar photovoltaic power generation may know, many solar panels on the market now use EVA adhesive films.

01 Why do solar panels use EVA film?

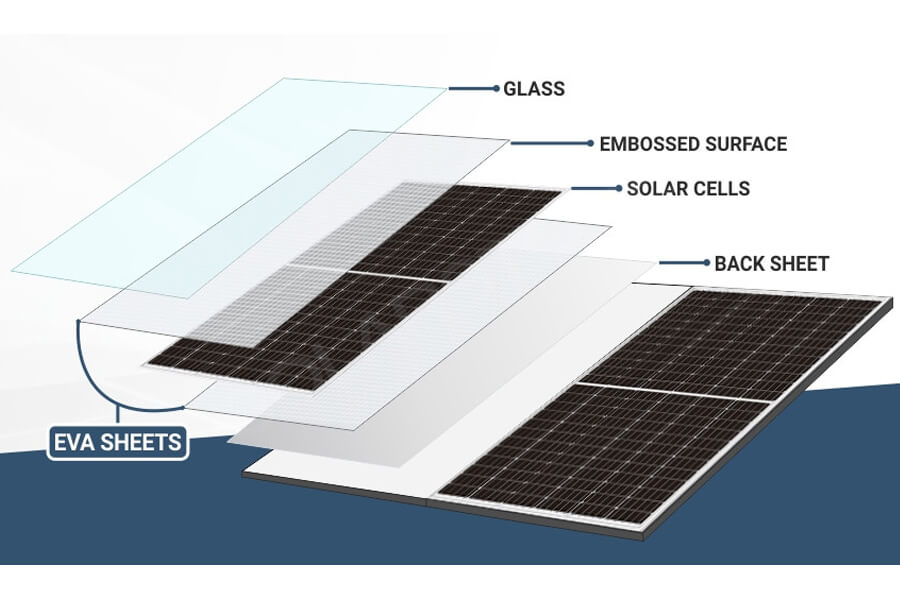

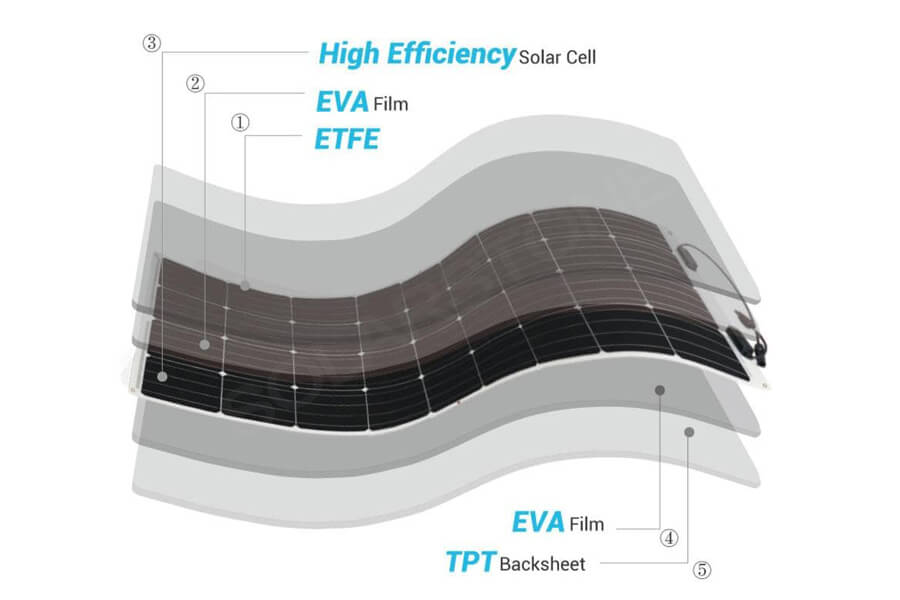

Because the silicon wafers in solar panels are very fragile, if the silicon wafers directly touch the outermost glass of the panel, they can be easily damaged.

At this time, it is necessary to use EVA adhesive films, which can be used to bond and fix tempered glass and power generation bodies, preventing the silicon wafers from directly contacting the outer glass, providing protection.

EVA adhesive film provides good protection while not affecting the power generation efficiency of solar panels. Moreover, EVA adhesive film has many advantages, such as excellent adhesion, durability, and optical properties.

Its light transmittance is up to 90% or more, and it can withstand high temperatures of 85 degrees Celsius and low temperatures of minus 40 degrees Celsius without thermal expansion and contraction, with good stability, under long-term ultraviolet radiation, there will be no cracking and aging, which is a strong guarantee for efficient power generation of solar panels.

02 What should we do when the EVA film lacks glue or does not dissolve?

Now we have learned that EVA adhesive films play a crucial role in solar panels, but sometimes in the application of solar products, EVA adhesive films can cause a lack of adhesive or insoluble problems.

The causes of the problems may be related to the material, or the EVA material may be affected by moisture or expired, which can lead to a lack of adhesive or insoluble EVA.

EVA lacks glue or does not dissolve, which can have a direct impact on the production process, affecting process integrity and product yield. So when we find such problems with EVA, how should we handle them?

First, at the source of EVA, qualified material suppliers should be selected, so that the quality inspection technology is excellent and the raw materials are guaranteed to prevent the occurrence of damped or expired EVA raw materials.

Secondly, during machine operation, strictly implement operational requirements and control important parameters such as lamination temperature and lamination time to avoid erroneous instructions and misoperation.

Thirdly, in accordance with experimental guidelines and specifications, conduct EVA cross-linking degree experiments as required, and control the cross-linking degree within 85% – 95%, and keep the experimental detection close.

Fourth, for materials purchased by different manufacturers, use different process conditions to adjust the parameters and indicators of the temperature and time of the solar panel lamination press, and change the cross-linking degree experimental detection standards.

Through the above measures, the probability of EVA glue shortage or insoluble situation is reduced, and the error rate is reduced. Non rework of production processes is a strong support and important guarantee for production efficiency.