1. Background

Solar panels are usually divided into two types: 60 cells solar panels and 72 cells solar panels: 60 cells solar panels can be handled and installed by one person, which are usually used in residential roof photovoltaic projects; 72 cells solar panels need two people to carry and install, which are usually used in large-scale photovoltaic projects.

The fierce competition in the photovoltaic industry has led manufacturers to make a fuss about the size. By increasing the battery specification from 156.75mm to 166mm (2019), the size of solar panels has increased slightly by 10%, and the area of 60 and 72 version solar panels has reached 1.8m2 and 2.2m2 respectively, which can still meet the installation of one person / two people.

The great success of 166 solar panels has also encouraged solar panel manufacturers to increase the area of large-size solar panels to about 2.6 M2 (2020). In addition to 72 versions of 182 solar panels (using 182mm side length solar cells), 55 versions of 210 solar panels (using 210mm side length solar cells) have also appeared, and the power of solar panels is close to 550W, The weight of double-sided double glass solar panels has also been pushed up to nearly 33kg.

With the continuous increase of size, many people only see the appearance and ignore the restrictions behind the large size. They simply think that the larger the better, and begin to shout out 600W, 700W or even 800W solar panels.

In fact, behind the ultra-high power is the supersize, and the supersize solar panel with an area of more than 2.6 M2 will not bring more value, but it will face a lot of risks after the size and electrical parameters exceed the boundary value, which should not be the development direction of solar panels.

2. Application risk of oversized solar panels

2.1 load risk of oversized solar panels

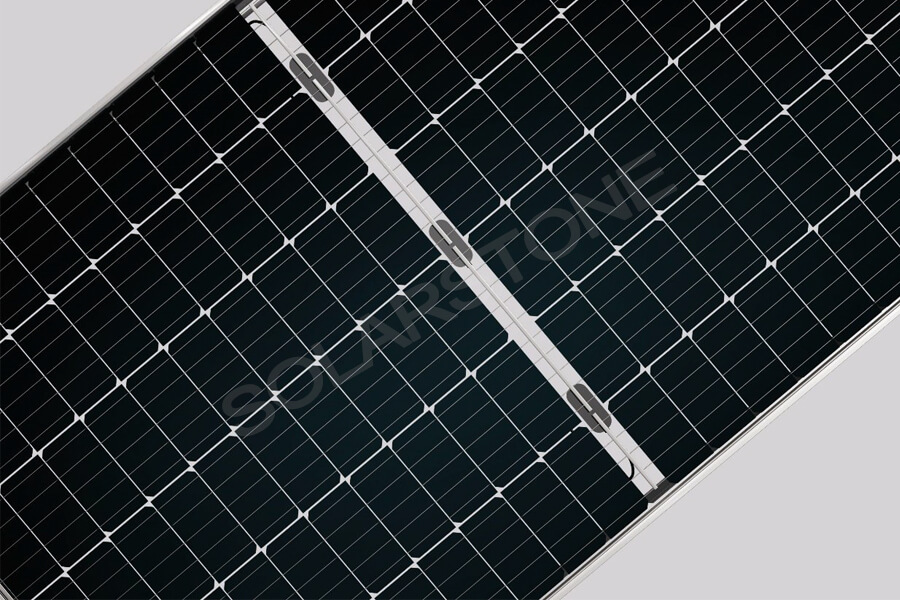

In addition to the risk of installation and handling, the application risk of oversized solar panels is mainly reflected in the mechanical load performance of solar panels. Due to the limitations of the weight and cost of solar panels, the glass thickness of solar panels cannot be increased, that is, single-layer glass solar panels use 3.2mm thick glass, and double-layer glass solar panels use 2mm + 2mm thick glass. When the glass thickness remains unchanged, the size of solar panels meeting the load requirements should be limited.

With the increase of the length and width of the solar panel, the stress of the frame continues to increase, and the super large solar panel faces a very high-stress risk. On the other hand, the increase of the size of the solar panel will increase the wind and snow pressure, the shear stress at the frame mounting point will increase accordingly, and the risk of frame tearing due to wind load will increase significantly.

In addition, the ability of solar panels to resist dynamic mechanical load will decrease with the increase in size. In addition, the super large glass used in super large solar panels has not been verified in mass production, so the risk in this regard will be more uncontrollable.

2.2 self-weight deformation of oversized solar panels

In addition to the increase of frame stress, only its own weight will lead to a significant increase in the deformation of oversized solar panels. When the area of solar panels is 3 ㎡, the self-weight deformation can reach 11mm. The influence of the widening of solar panels on the deformation is greater than that of lengthening.

Therefore, during the use, transportation and handling of solar panels, such a large deformation is bound to greatly increase the risk of cell cracks and bring hidden dangers to the power generation income of the power station.

2.3 shipping risk of oversized solar panels

Previously, some enterprises claimed to have found a packaging scheme for oversized solar panels, but did not publish it. In fact, challenging the existing packaging methods will significantly increase the risk of transportation damage or use on the project site. Due to the limit of the door height of 40hc container, the width of solar panel has reached the limit in the beginning of 1.1m.

If the width is further increased, either tile packaging or vertical packaging shall be adopted. The tiled packaging will inevitably increase the damage rate during shipping. Even a 2% increase in the damage rate is unbearable for the manufacturing enterprise. If the cracks are not found by the investor and the products are applied in the power station, it will bring hidden dangers to the power generation income of the power station; The erected packaging increases the risk of packaging dumping at the project site. Once the super large and heavy solar panel is pressed against the workers, it is very dangerous.

3. Why does oversized solar panels bring no value

3.1 labor handling cost

The obvious value of large-size solar panels is that they can reduce the cost of manual handling and installation. For example, the solar panels used in large power stations are changed from 60 version to 72 version, which will not affect the handling efficiency by block. The installation cost of a single w will be reduced immediately.

In developed countries such as the United States and Europe with high labor costs, This part of the savings is obvious. The size of solar panel is increased from 2 ㎡ to 2.2 ㎡, and the principle of labor cost saving is the same.

Then, it is increased from 2.2 to 2.6 ㎡. For areas with small topographic relief, the handling efficiency is not affected much. However, if the size and weight of solar panels are too large, it will lead to the improvement of workers’ fatigue, the difficulty of installing solar panels into the support will also be significantly improved, and the damage rate of installation will increase significantly after fatigue accumulation.

The width of solar panel is usually equal to the natural opening distance of human arms. If it is too wide, the grip stability and human control of solar panel will be significantly reduced, and it is the limit to increase from 1m to more than 1.1m; The long length of solar panels will also reduce the stability of two people’s handling, especially increase the handling pressure when the terrain has certain ups and downs.

In terms of the weight of solar panels, the handling weight of an adult man should be 25kg. The handling weight of two people is not simply multiplied by 2, but needs to be multiplied by a factor of 0.666, i.e. 25 × two × 0.666 = 33.3kg, the handling efficiency beyond the limit will drop sharply.

3.2 cost of support and foundation

The reduction of BOS cost caused by large-size solar panels mainly comes from the saving of support and foundation cost, which accounts for 80%. The cost savings of support and foundation essentially come from the savings brought by large support design, including the number of pile foundations saved by long support and the single w cost of diluted support and foundation by wide support.

Therefore, oversized solar panels do not necessarily lead to cost savings in support and foundation: for mountain power stations, the length of support itself cannot be too large, and oversized solar panels themselves will not be applicable;

For the flat power station, the length of the tracking support is limited. Considering the thermal expansion and cold contraction of steel materials, the length of the fixed support will actually be limited to about 120m. Considering the difficulty of installation of the support and solar panel, the width of the support is also limited.

3.3 cost savings for cable & electrical equipment

The savings on cables and electrical equipment (combiner box or series inverter) come from high string power. Therefore, large-size solar panels usually keep the voltage constant and increase the current, so as to increase the single string power, so as to save the length of cables and the number of combiner boxes (or series inverter).

However, considering the cost converted by the energy loss on the cable, the current with the best comprehensive cost when using 4m ㎡ cable is 14 ~ 15A; In terms of combiner boxes, due to the limitations of aluminum alloy DC cable selection and fuse specifications, super large-size solar panels with super large current will not save the number of combiner boxes;

When the IGBT chip of the series inverter remains unchanged, 15A also basically reaches the limit, and the excess current can not be used, resulting in saving the number of equipment. On the contrary, the product is fragmented, and the cost of life cycle management and maintenance will increase. In fact, the savings brought by high current can be realized outside the solar panel. By paralleling two circuits into one (without fuse), the consumption of photovoltaic cable can be significantly reduced by using 6m ㎡ photovoltaic current.

In contrast, the high current of solar panel faces a significant increase in the heating loss on the welding strip, bus bar and its own cable, It leads to the decrease of solar panel efficiency, the increase of cost and even the increase of working temperature, which is contrary to the development direction of increasing solar panel efficiency.

4. Summary

To sum up, compared with the current large-size solar panels, super large-size solar panels can not bring value in system cost, but there are a series of use risks, most of which are inherent in super large size and difficult to improve.

Therefore, power station investors should avoid being confused by the surface 600W and 700W power, and make rational choices based on kwh cost and risk-benefit analysis.