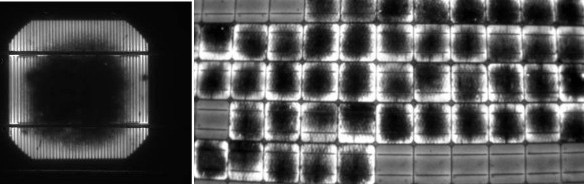

Reason for inefficiency

1. Mix low-grade solar cells into high-end solar modules (raw material mixing/or in-process mixing).

Impact of solar modules:

1. The overall power of solar modules decreases, and the power of solar modules decays significantly in a short period of time.

2. Low efficiency areas will generate heat and burn out solar modules.

Preventive measures:

1. When placing solar cells in the production line, different grades of solar cells should be distinguished to avoid mixing. The grades of solar cells in the repair area should also be labeled to avoid misuse.

2. EL testers should strictly inspect to avoid the leakage of inefficient solar cells.

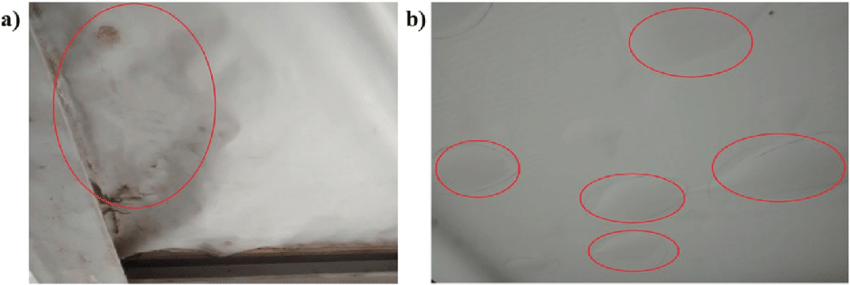

Reasons for silicone bubbles and gaps

1. Silicone bubbles and gaps are mainly caused by bubbles inside the silicone raw material or unstable air gun pressure.

2. The main reason for the gap is that the employees use non-standard adhesive techniques.

Impact of solar modules:

1. Where there are gaps, there will be rainwater entering. After rainwater enters, the solar module will generate heat during operation, which will cause layering.

Preventive measures:

1. Please ask the raw material manufacturer to improve and strengthen IQC inspection.

2. The glue application techniques of personnel should be standardized.

3. After applying the glue, the personnel should perform their own actions. The cleaning personnel should strictly inspect it.

Reason for missing glue application

1. The personnel did not work seriously, resulting in missing glue.

2. The placement of solar modules on the production line is not standardized, and personnel pull the wrong product into the next process.

Impact of solar modules:

1. Failure to apply glue can cause rainwater or moisture to enter and cause the solar module to catch fire.

Preventive measures:

1. Strengthen personnel skill training and enhance self inspection awareness.

2. The production line is strictly arranged according to the principle of “three fixed products” to avoid misuse.

3. Clean the solar modules and strictly inspect the packaging to avoid defects and leakage.

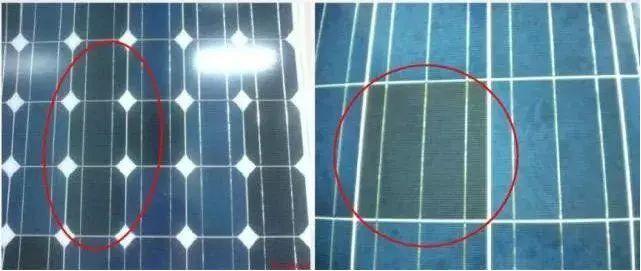

Reason for lead solder failure

1. The personnel’s operation techniques are not standardized or serious, resulting in missed welding.

2. The soldering iron temperature is too low, too high, or the welding time is too short, resulting in faulty soldering.

Impact of solar modules:

1. The power of the solar module is too low.

2. Poor connection leads to increased resistance, causing the solar module to burn out due to ignition.

Preventive measures:

1. Strictly require operators to perform SOP operations and standardize their operational techniques.

2. Check the temperature of the soldering iron on time and standardize the welding time.

Reason for non curing of silicone in junction box

1. The silicone ratio does not meet the process requirements, causing the silicone to not solidify.

2. The glue hole A or B is blocked without glue, resulting in non curing.

Impact of solar modules:

1. Silicone non curing adhesive will flow out from the edge of the junction box gap, and the leads inside the box will be exposed to the air. In case of rain or moisture, it can cause the solar module to catch fire.

Preventive measures:

1. Strictly follow the regulations to confirm the drying action of the silicone watch every hour.

2. Regularly confirm whether the silicone ratio meets the process requirements.

3. The cleaning process should be strictly controlled to ensure that the silicone gel is 100% cured.

Reason for EVA small strip turning yellow

1. EVA strips are exposed to the air for a long time, causing mutations.

2. EVA mutates due to contamination by flux, alcohol, etc.

3. Chemical reaction occurs when used in combination with EVA from different manufacturers.

Impact of solar modules:

1. The customer does not accept the appearance defect.

2. May cause delamination phenomenon.

Preventive measures:

1. After opening, EVA should be strictly used up within 12 hours according to the process requirements to avoid prolonged exposure to the air.

2. Pay attention to the 5-second cleaning of the material placement area to avoid contamination during the processing.

3. Avoid using it with EVA from different manufacturers.

Reasons for foreign objects and red pen marks on glass surfaces

1. The stacking and glass loading area is not clean for 5S, causing foreign objects to be pressed inside the solar module.

2. Personnel found defects and marked them properly. After the review, they did not clean them in a timely manner and directly packaged them.

Impact of solar modules:

1. Impact on the overall appearance of solar modules. Preventive measures for complaints.

2. Perform 5S cleaning on the stacking and glass loading processes to avoid the occurrence of foreign objects.

3. After discovering defects, it is prohibited to mark the solar module and directly record the location of the defect on the process card.

4. The placement of products on the production line strictly follows the “three fixed” principle of labeling and placement.

Reason for color difference of solar modules

1. The color difference of solar modules is caused by uneven coating during raw material processing.

2. The welding machine did not distinguish the placement of solar cells according to color when placing them.

3. The repair area did not undergo color differentiation confirmation, resulting in mixed color differences.

Impact of solar modules:

1. Affects the overall appearance of solar modules and causes complaints.

Preventive measures:

1. Provide feedback to improve raw materials and conduct strict inspection and management of incoming materials.

2. The welding machine strictly requires color differentiation during feeding to avoid mixing.

3. Mark the color level of solar cells in the repair area, and make your own actions during and after rework to avoid color differences caused by using the wrong solar cells.