Mechanical load testing of photovoltaic modules

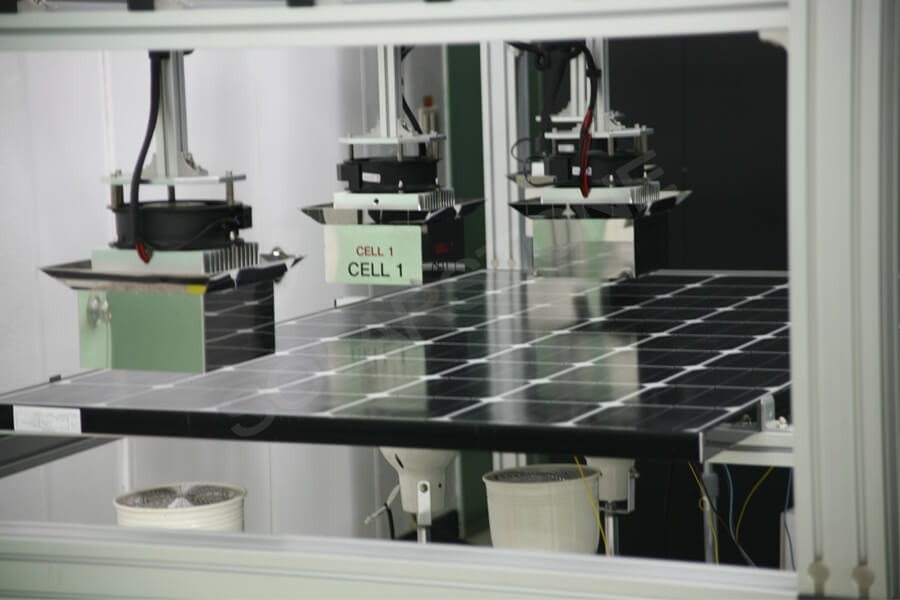

Mechanical load testing is a gradual loading process on the surface of photovoltaic modules, monitoring possible short circuits and open circuits, appearance defects, electrical performance degradation rate, insulation resistance, etc. during the experiment to determine the ability of photovoltaic modules to withstand static loads such as wind and snow.

Mechanical load testing can be conducted using a solar photovoltaic module mechanical load testing machine, which can determine the ability of photovoltaic modules to withstand static and dynamic loads such as wind, snow, or icing at different installation angles.

Widely used for testing the compressive strength of solar photovoltaic modules, it adopts dynamic holding pressure technology and simulates load experiments to understand the compressive capacity of products under load conditions.

The wet hot and wet cold experiment of photovoltaic modules

The wet hot and wet cold experiment is to place photovoltaic modules in a climate chamber with automatic temperature control and internal air circulation, so that the photovoltaic modules can cycle back and forth at a certain temperature and humidity, maintain a certain recovery time, monitor possible short circuits and open circuits, appearance defects, electrical performance degradation, insulation resistance, etc. during the experiment, to determine the ability of photovoltaic modules to withstand high temperature, high humidity, low temperature, and low humidity.

Damp heat and wet cooling can also be carried out in solar photovoltaic module temperature and humidity cycling experimental boxes, solar photovoltaic module humidity cycling boxes, solar photovoltaic module humidity cooling boxes, and other equipment.

These experimental chambers can simulate complex natural environments such as low temperature, high temperature, high humidity, low temperature and low humidity.

Hail experiment on photovoltaic modules

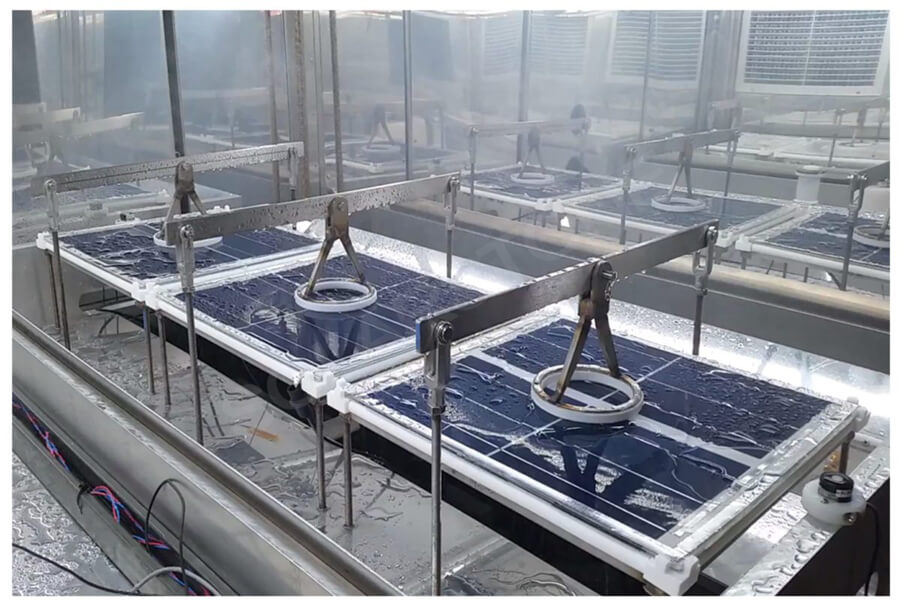

The hail experiment is conducted by using artificially made ice balls or steel balls instead of hail to impact photovoltaic modules from different angles with a certain amount of momentum, detecting the appearance defects and electrical performance degradation rate of photovoltaic modules, in order to determine the ability of photovoltaic modules to withstand hail impacts.

The hail experiment of photovoltaic modules can be conducted through the solar photovoltaic module hail impact testing machine. The working principle is that the air compressor compresses the air into the air storage tank, and an external pressure gauge and a certain inner diameter (such as 25mm) gun barrel are connected. An electromagnetic valve is installed at the connection, which is controlled to open.

Install a photoelectric speed measuring device at the front end of the barrel. Adjust the pressure gauge to achieve the required impact speed for the ice hockey puck. Create an ice hockey mold with a certain inner diameter (such as 25mm), place the ice hockey ball inside the barrel, open the solenoid valve, and compress air to push the ice hockey ball to impact the solar photovoltaic module at a certain speed (such as 23m/s).

After being hit by ice hockey balls, photovoltaic modules undergo visual inspection, I-V testing, and insulation resistance testing to determine whether the quality of the photovoltaic modules is qualified.

UV aging experiment of photovoltaic modules

The UV aging experiment is used to test whether solar photovoltaic modules have anti-aging and attenuation ability when exposed to high humidity and high UV radiation fields, and can be conducted through a UV aging test box. The UV aging test chamber generally uses a fluorescent UV lamp as the light source.

By simulating the ultraviolet radiation in natural sunlight, the material is subjected to accelerated weather resistance experiments to obtain the results of the material’s weather resistance.