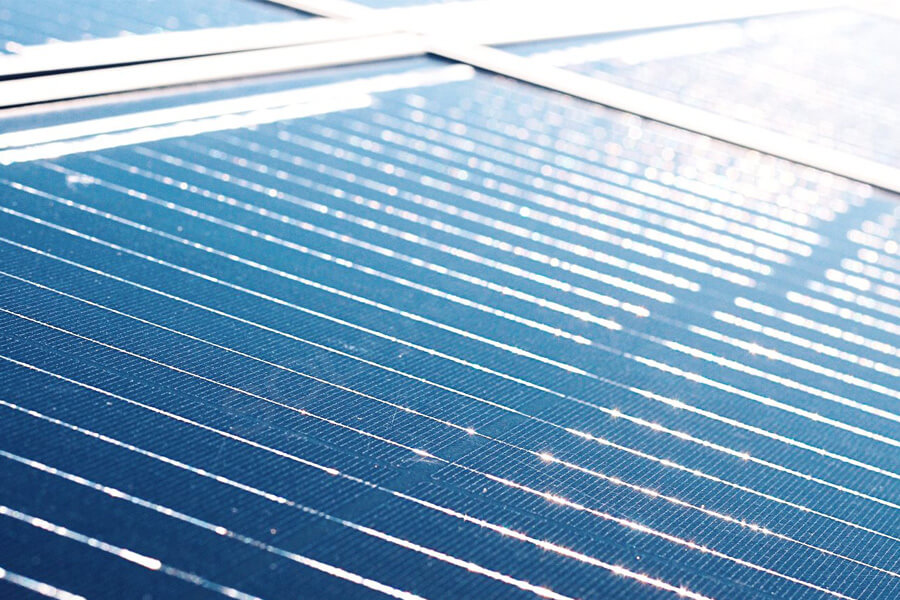

PV welding strip is an important part of every mainstream solar panel, which is used to interconnect solar cells and provide connection with junction box. PV welding strip is tinned copper strip, with a width of 1-6mm, a thickness of 0.08-0.5mm and a thickness of 10-30 μ M thick flux coating.

There are two forms of PV welding strip applied to photovoltaic modules: interconnection strip or bus bar and PV bus bar. In typical silicon solar cells, both are needed.

The interconnection strip is directly welded on the silicon crystal to connect the solar cells in the solar panel with each other. The interconnection belt carries the current generated by the solar cell to the PV bus. PV bus bar is a hot-dip tinned copper conductor installed around the periphery of solar panel. The PV bus connects the interconnection strip to the junction box. Thin film solar panels generally only need bus bars.

PV welding strip is the key component of solar panel, which is an important factor to improve the efficiency and durability of solar panel. The high efficiency and durability of solar panels can only be achieved with high-quality PV welding strips properly installed in solar panels.

High quality PV welding strip can also improve the production efficiency of solar panels and reduce the scrap rate. The quality of PV welding strip and its welding to solar cells are important factors to ensure the efficiency and durability of solar panels.

1. At present, the welding strips in the market are mainly divided into silver containing and silver free welding strips. In addition to being expensive, the silver containing welding strip has its own advantages:

1) Increase the metallurgical bonding degree between solder and the metal to be welded. After welding, the mechanical strength and conductivity will be better.

2) After adding silver, the melting point of ternary alloy is lower than that of binary alloy, and its weldability and fluidity are improved

3) The resistivity will be reduced and the high temperature resistance will be improved.

2. The resistance of the welding strip is mainly determined by the size and specification of the welding strip itself and the material of the copper substrate. The composition of the tin coating on the surface will not significantly affect the resistance of the welding strip.

Increasing the width or thickness of the welding strip can reduce the resistance of the welding strip. This improvement can play the same role in both traditional welding methods and new low-temperature connection methods such as conductive silver glue or conductive tape connection.

However, the welding strip wider than the width of the front electrode will block the incident light and cause current loss. We recommend using thicker welding strips without affecting the fragment rate.

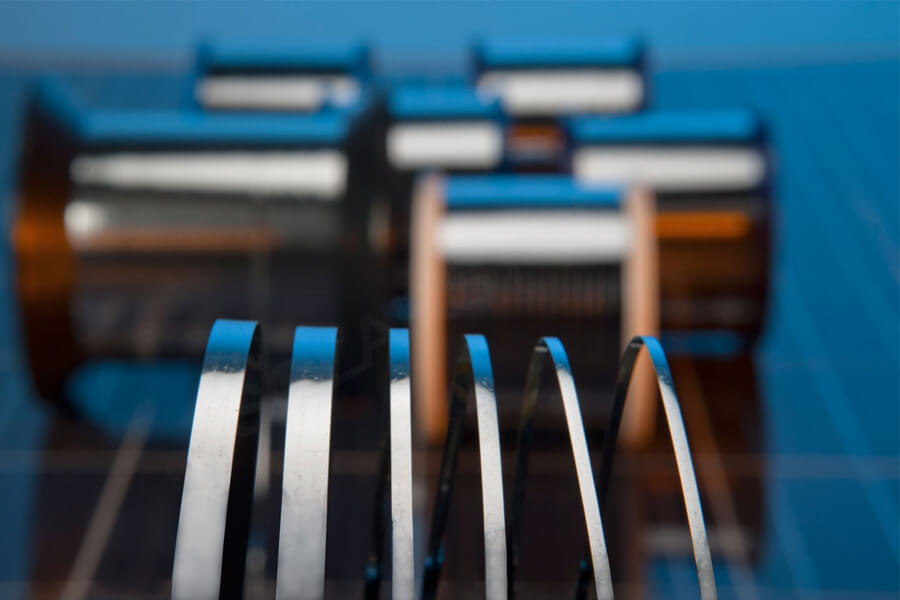

3. The solar cell covered by the welding strip cannot absorb sunlight. Some welding strip companies have launched reflective welding strips. The front of the welding strip is silver plated and calendered with a longitudinal groove structure.

This structure can reflect the light incident on the welding strip to the inner surface of the glass layer of the module at a certain angle, and project it back to the battery surface after total reflection on the glass air interface. The captured light can make the module generate additional power, which can theoretically improve the efficiency of the module by about 2%.

4. Key quality parameters of PV welding strip

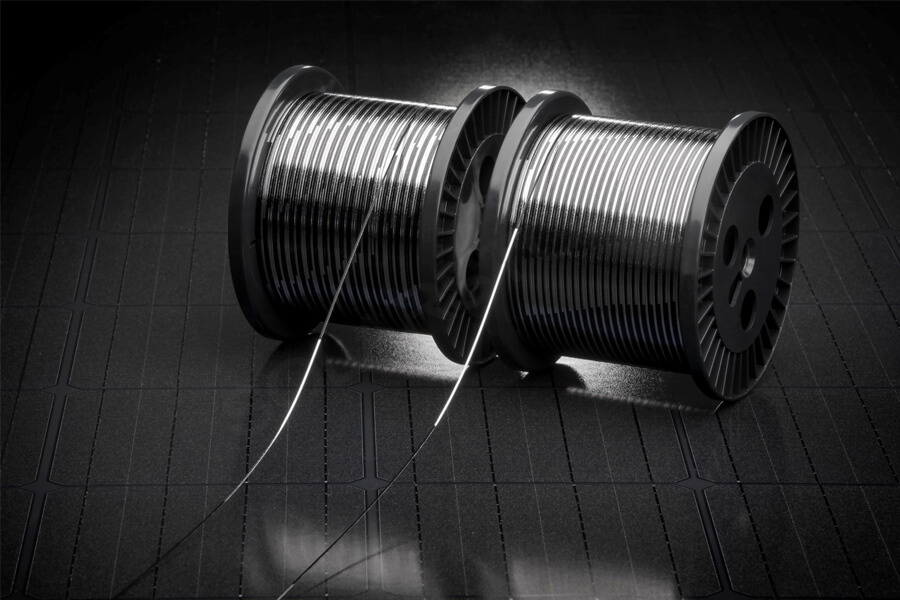

The performance index of PV welding strip is important in itself. The type and purity of copper determine the conductivity of the material and the maximum softness of the welding strip. The composition of the flux, the thickness of the covering layer and the covering composition affect the quality of the solder joint, thus affecting the durability of the solar panel.

The high extensibility of PV bonding strip is very important to prevent solder joint failure between bus bar and interconnection bonding strip. This failure may occur due to the extension / tension caused by temperature oscillation during the operation of solar panel.

During the service life of the solar panel, the continuous and sometimes particularly fierce temperature oscillation makes the solder joint withstand the test during the service life of the solar panel (an average of 25 years).

The two parameters that are crucial to most PV strip manufacturers are bending and yield strength. Many PV strip manufacturers find it difficult to obtain a high level of strip flexibility while ensuring its straightness.

Obtaining sufficient flexibility and low curvature may mean the difference between winning and losing the supply contract. Therefore, manufacturers must strive to improve their rolling, annealing, tin plating and material treatment technologies to meet the increasing requirements of product performance indicators.

Therefore, the influence of welding strip on component power generation is not only the design material of welding strip itself, but also the selection of welding strip, lamination process and quality control of welding strip production. We need to understand the welding strip from all aspects, although the industry may pay more attention to packaging materials and solar cells.