Photovoltaic modules, due to their unique material characteristics, are prone to cracking and damage, and even subtle cracks are difficult to detect. Although more protection is provided during production or transportation, cracking is sometimes difficult to avoid.

Generally speaking, the causes of hidden cracks in photovoltaic modules are nothing more than these situations: uneven surface stress caused by external force compression during welding or transportation;

In a low-temperature environment, without preheating in advance, there is a rapid increase in temperature within a short period of time, and there is a temperature difference between the inside and outside, leading to expansion and cracking; Sometimes the instantaneous high temperature during welding is also the culprit causing hidden cracks.

In order to reduce the occurrence of hidden cracks in photovoltaic modules, targeted preventive measures need to be taken for photovoltaic modules. For example:

During the production process, avoid being squeezed and collided by external forces. All potential equipment or items that may cause illness in the workplace should be cleared. When handling, the force should be placed as much as possible at the point of force to avoid uneven stress.

During the welding process, the temperature of the photovoltaic module should be appropriate, and preheating in advance is the best. In addition, the melting temperature of the soldering iron should also meet the operational requirements, and the operating methods should be standardized to prevent external pressure and collision.

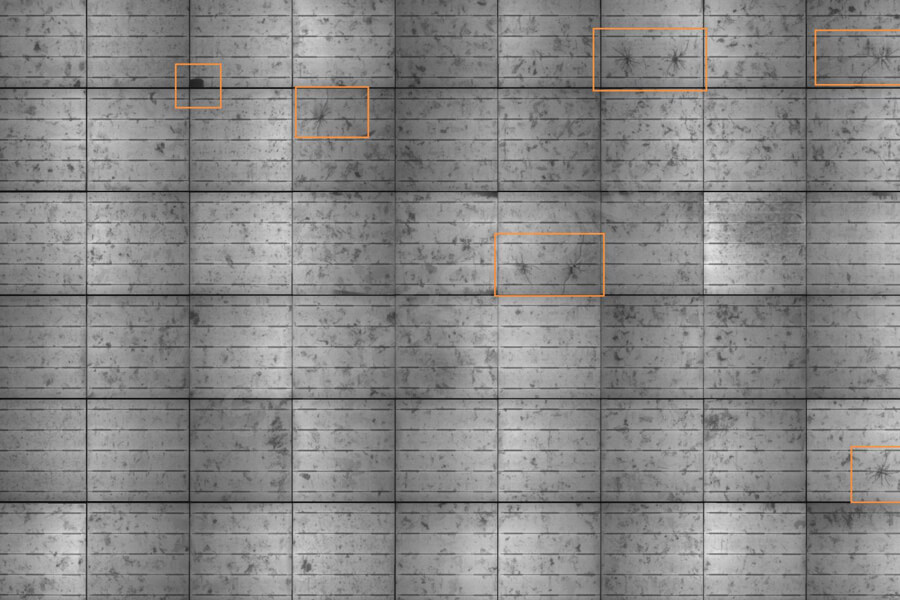

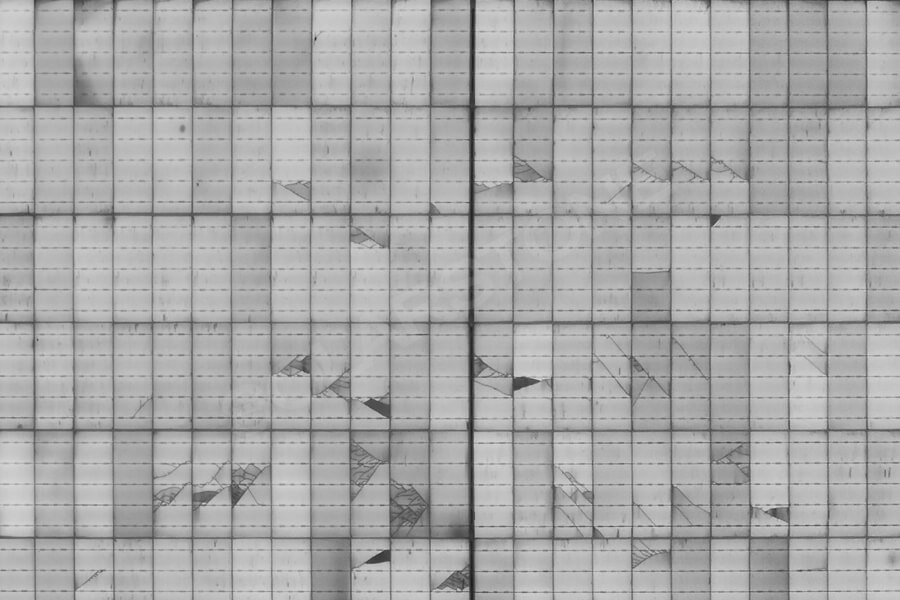

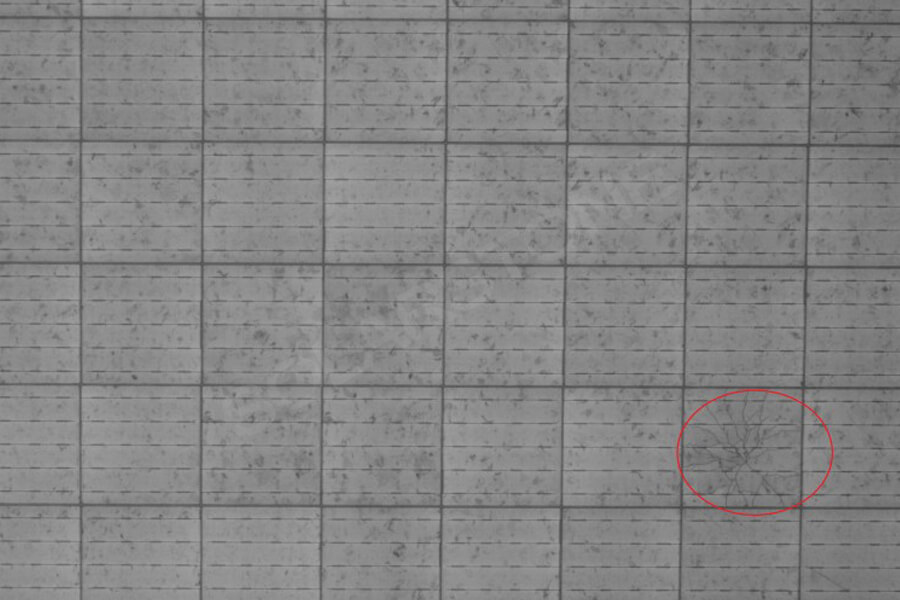

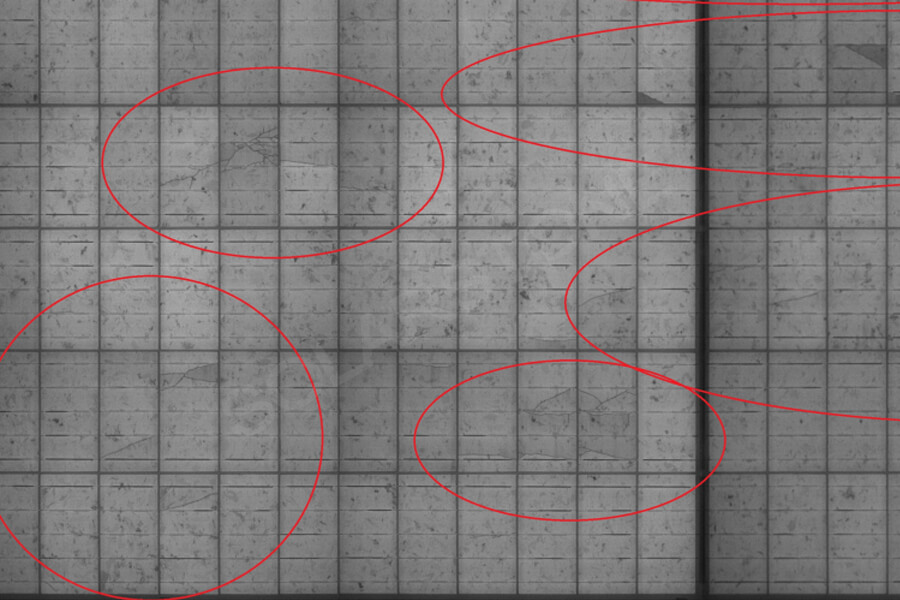

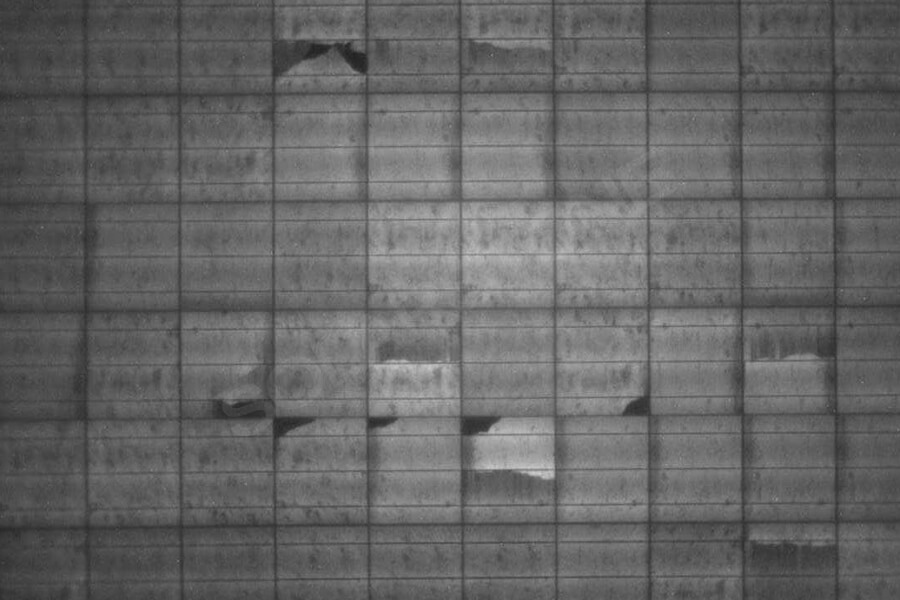

During EL testing, it is necessary to strictly analyze the thin black bands generated on each image, identify the cause of the problem, eliminate the possibility of hidden cracks, and eliminate hidden cracks in the testing process.

When hidden cracks are found in the image, open the backplane and EVA to verify. If possible, use a flashlight to repeatedly verify and confirm. The photovoltaic module with hidden cracks should be treated with zero tolerance and promptly removed for replacement.

Photovoltaic module cracking is a long-standing problem, and what can be done is to avoid cracking as much as possible, reduce the occurrence of cracking, and improve the product process level and quality of photovoltaic modules.