In today’s outdoor lighting, the street lights on both sides of the road, the landscape lights in parks and squares, courtyard lights, and those warning signs have joined the solar energy design, which can meet the power demand without municipal power. While reducing the installation cost, it also greatly saves energy and reduces the pressure of municipal power.

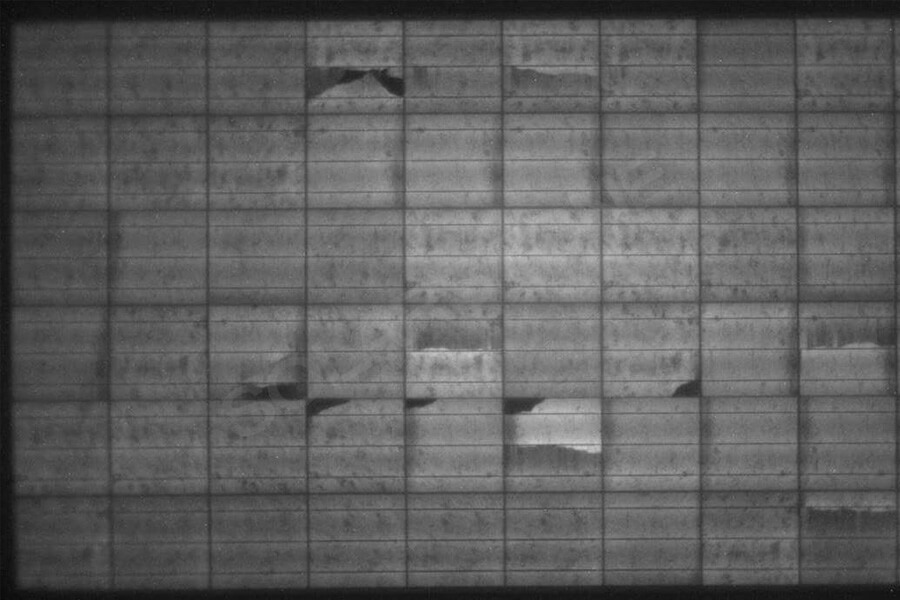

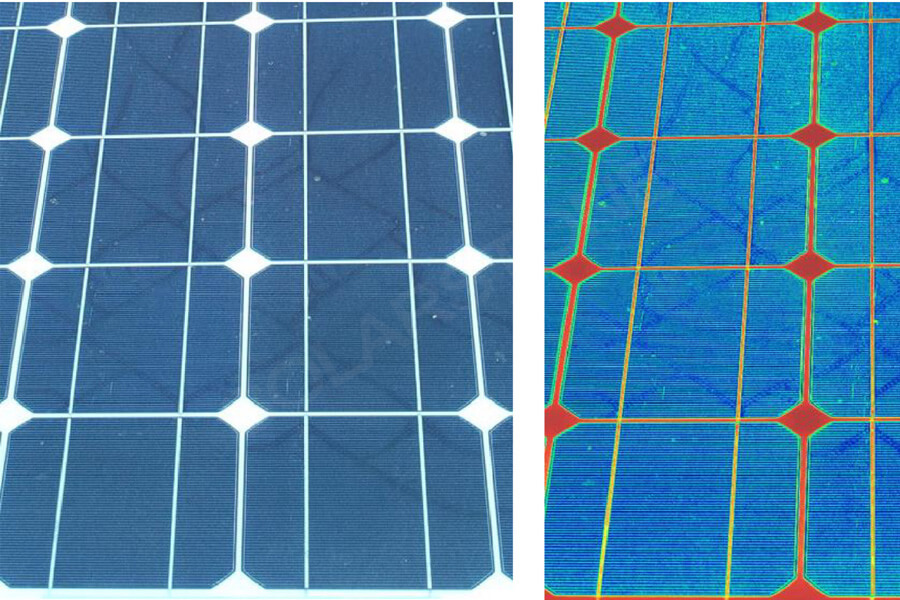

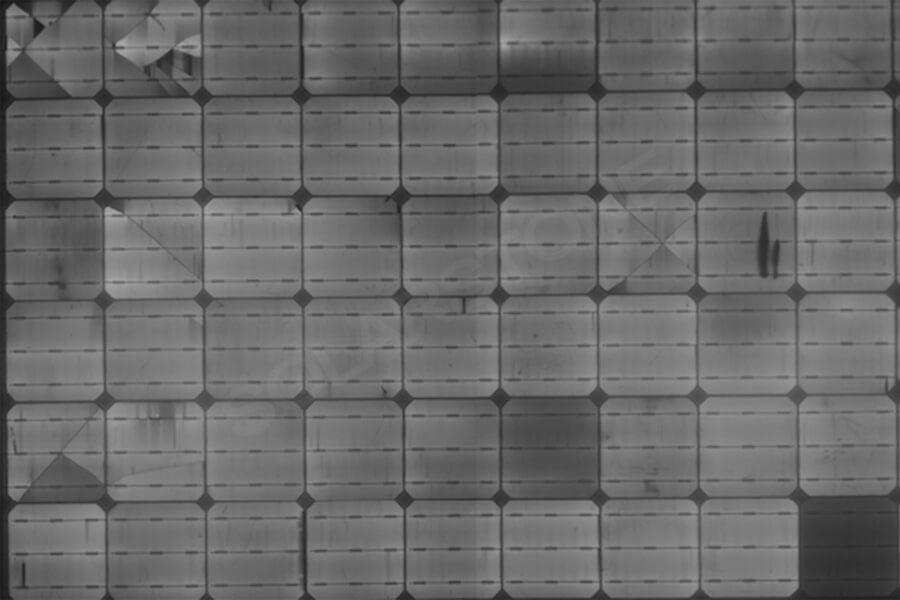

Solar panels are particularly important in these new lighting designs. However, it should be noted that solar panels are made of polycrystalline silicon, monocrystalline silicon, and other crystal structure materials, which are prone to hidden cracks.

These hidden cracks are difficult to find with the naked eye. Their existence will accelerate the power attenuation of solar panels, and then affect the overall service life, Therefore, we must control it well.

1. Consequences of cracks

When the grid line is damaged due to the hidden crack, the collected current will not be output normally, which will lead to partial or even total failure of the solar cell, affect the power output of the solar cell panel, cause its continuous attenuation and affect its service life;

At the same time, the crack problem of solar panels continues to expand under mechanical load, which may also lead to open circuit damage and hot spot effect.

2. How are cracks caused?

To solve the problem of hidden cracks in solar panels, we must first understand how these hidden cracks are generated, so as to suit the remedy to the case, avoid or reduce the generation of hidden cracks. There are many reasons for the hidden cracks in solar panels. Let’s take a specific look below.

a. Purity of solar cells

Solar panels are made of crystalline silicon, and the conductivity of pure silicon itself is very weak. In order to strengthen its conductivity, boron or phosphorus and other trace impurities are usually added to enhance its conductivity.

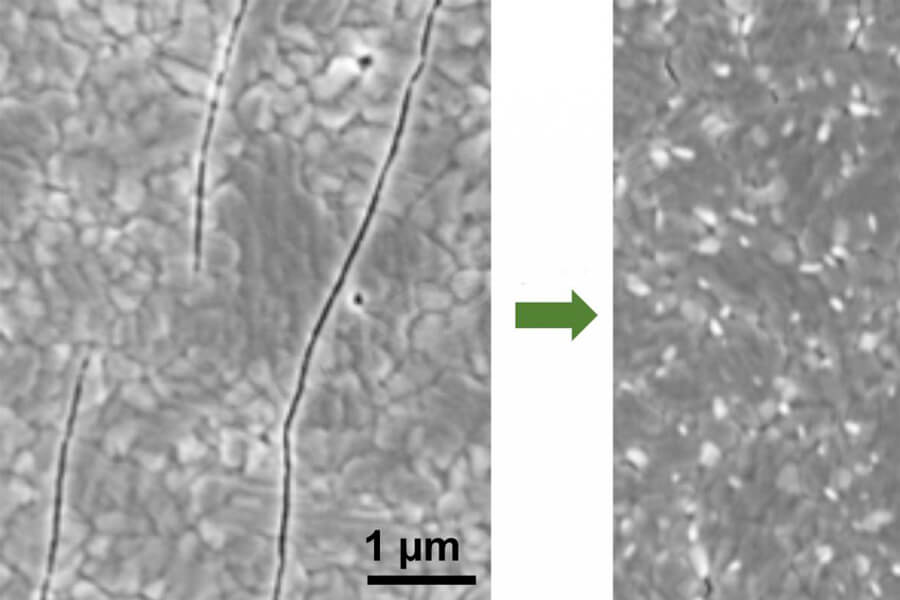

But at the same time, it should be noted that if the silicon material contains excessive oxygen, carbon, and other impurities, resulting in insufficient purity of silicon, it is easy to cause problems such as stacking faults, dislocations, and warpage of solar cells, reduce the loading and unloading strength of solar cells, and in the later processing process, whether it is mechanical or thermal stress, It is easy to cause the crack problem of solar cells.

b. Problems of tin-coated solder tape

Solar panels are composed of solar cells in series. In this process, welding will be involved. Generally, there are several hidden cracks near the welding strip. If the surface of the welding strip is coated very thick, it is convenient for welding, but it is easy to lead to tin accumulation, ball tin, etc.

In the later lamination, the pressure will often focus on this solder joint, and the uneven stress will naturally cause hidden cracks. In addition, if the solder strip itself is too thick or too hard, it will also lead to hidden cracks of solar cells to a certain extent.

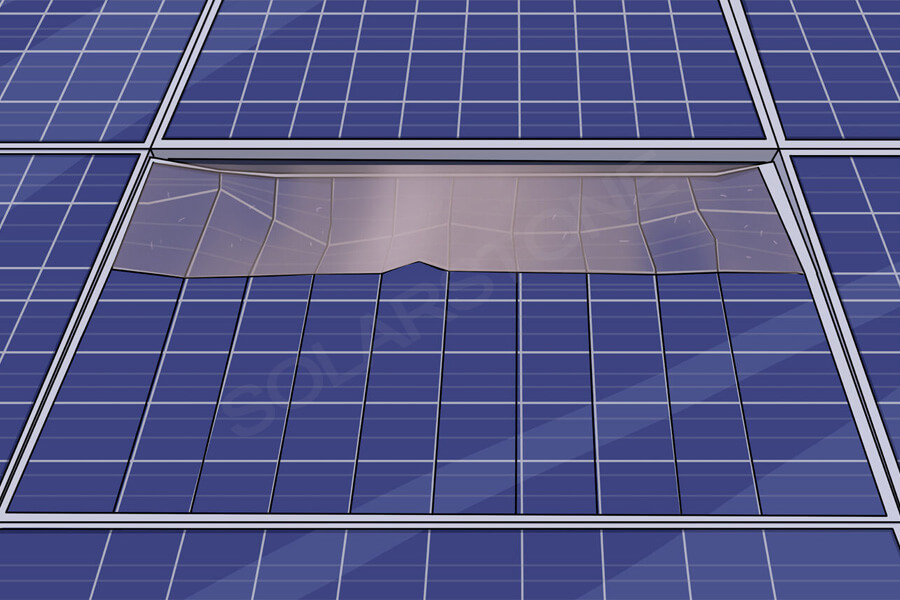

c. Thickness of tempered glass

If the area of the solar panel is too large and the thickness of the tempered glass is too thin, there will be insufficient bending strength. Under the action of gravity, bending is easy to occur, which will also lead to the problem of the hidden cracks of the solar panel.

d. Unhealthy operation during transportation and installation

For example, dragging on the ground at will, or knocking and colliding with hard objects such as a hammer, can easily lead to the hidden crack of solar panels.

3. How to avoid hidden crack

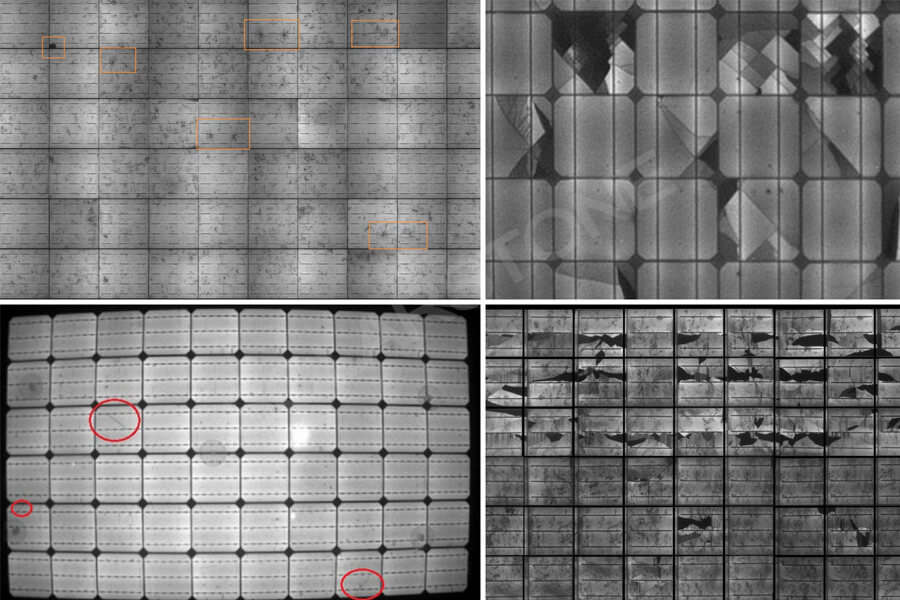

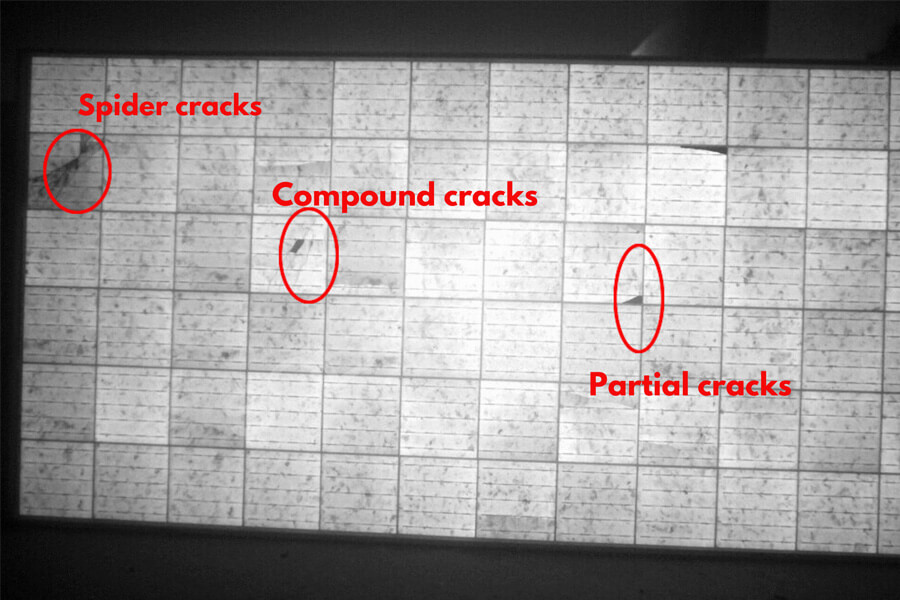

In fact, the impact of hidden cracks on solar panels is different. The sunlight irradiates the solar panel to complete photoelectric conversion, in which the generated current depends on the main grid line on the surface of the solar panel and the fine grid line perpendicular to the main grid line to collect and export.

If the crack is perpendicular to the main grid line, it will hardly affect the fine grid line, and generally speaking, it will hardly cause the failure of solar panels; However, when the crack leads to the fracture of the fine grid line, the fine grid line will not be able to transmit the collected current to the main grid line, which will lead to the failure of the solar panel.

The hidden crack that can lead to the fracture of the fine grid line is generally parallel to the main grid line, and the effect caused by the failure of the crack inclined at 45 ° is about 1 / 4 of the former.

In addition, it should be noted that if the failure area of the solar cell is less than 8%, it will have little impact on the solar panel. Therefore, there is no need to be too nervous about the cracks on the solar panel. Just pay attention to the identification, but this does not mean that the hidden crack problem of the solar panel can be taken lightly. Then, how to avoid it?

a. Ensure the purity of silicon materials

When producing solar panels, manufacturers should pay special attention to the selection of silicon materials in the early stage to ensure the purity of silicon materials and the mechanical strength of solar panels.

b. Specification welding

For the selection of copper strip, the base material of tin-coated welding strip, we should first pay attention not to be too hard or too thick.

When cutting, it should be as short as possible so that the starting and receiving welding points can be far away from the edge of the solar cell, which can effectively ensure that there will be no great welding stress during lamination or other operations in the later stage, of course, the premise is to ensure that the current can output enough.

c. The thickness of tempered glass matches the area of the solar panel

Generally speaking, the thickness of tempered glass used for solar panels is about 3mm ~ 3.4mm. For general solar panels, the bending strength is sufficient, and it will not bend and sink due to gravity, which will affect the solar cell itself. However, if the area of solar panels is too large, it is more appropriate to use tempered glass with a thickness of 4mm.

d. Reduce violent operation during installation

During installation, avoid the impact or extrusion of hard objects. Handle with care. Be careful when there is a problem that needs to be adjusted. Do not directly knock or hammer the solar panel itself.