Application advantages

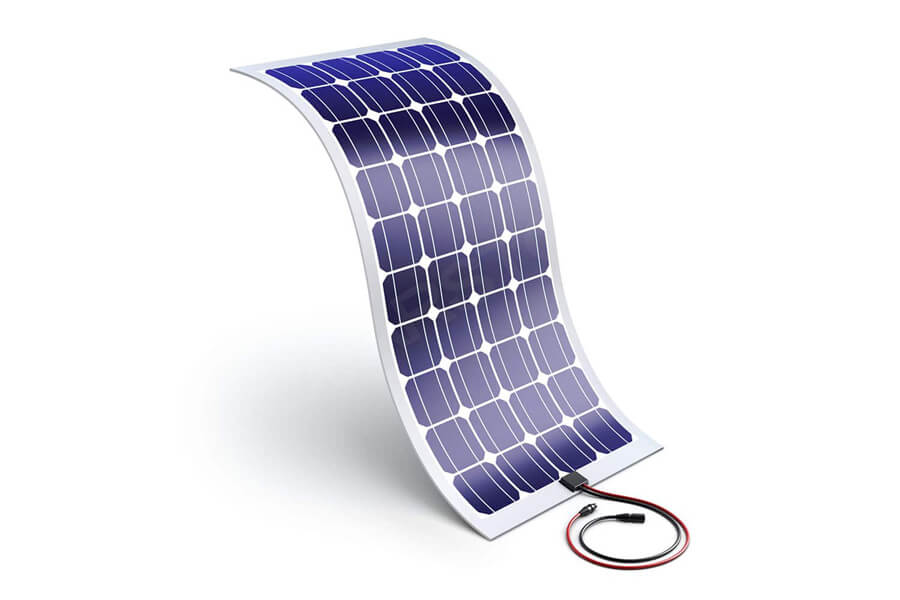

Soft: The material is soft and can be assembled on various surfaces to achieve various innovative applications.

Lightweight: The substrate is made of plastic or metal foil, which is lightweight and suitable for application scenarios with special weight requirements.

Safety: Using plastic or metal foil instead of fragile glass as a substrate is more sturdy, safe, and durable than traditional crystalline silicon or other types of thin film batteries.

Adjustable size: The size can be customized according to customer needs.

The superior characteristics of soft, lightweight, safe, durable, and customizable production of flexible solar cell substrates have led to a rapid increase in market demand.

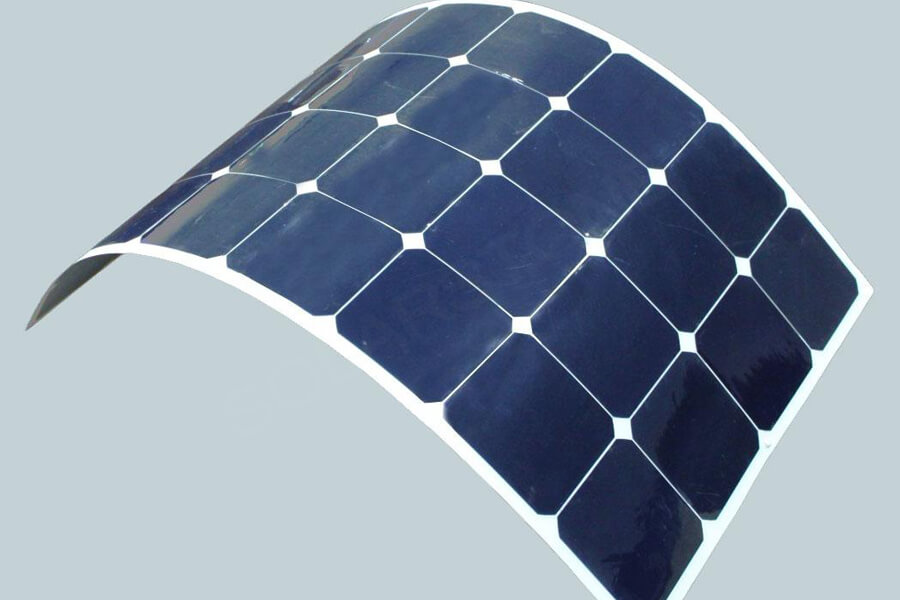

Classification of flexible solar cells

Flexible solar cells mainly include four categories: flexible silicon thin film solar cells, flexible copper indium gallium selenium solar cells, flexible cadmium telluride solar cells, and flexible perovskite thin film solar cells based on the different optoelectronic materials of the absorption layer.

The flexible substrate materials used mainly include metal foil and plastic. Metal foils include stainless steel, molybdenum, titanium, aluminum, copper, etc., while plastics include polyimide (PI), polyethylene terephthalate (PET), and polyethylene naphthalate (PEN).

At present, there are commercial components (solar panels formed by sealing several individual cells in series) for flexible solar cells, including flexible silicon thin film solar cells and flexible copper indium gallium selenium solar cells.

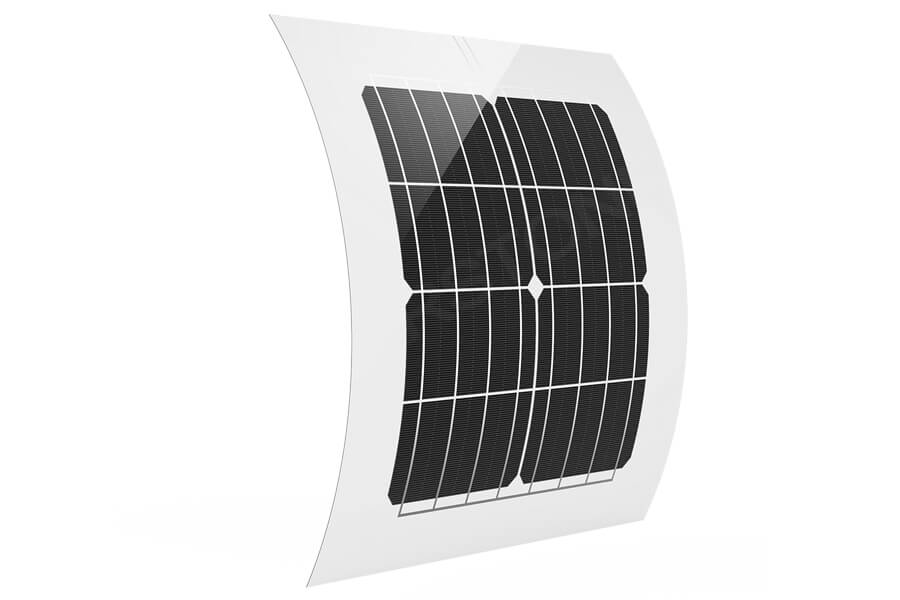

Application prospects of flexible solar cells

Flexible solar cells have the advantages of being lightweight, bendable, easy to carry and transport, and can be applied in the fields of national defense and military industry such as satellites, airships, drones, and individual equipment.

They meet the special needs of near space equipment, field military information equipment, solar powered drones, high-altitude detection equipment, as well as civil fields such as photovoltaic building integration and wearable intelligent devices, and have broad market prospects.

After years of development, the efficiency of flexible solar cells has been greatly improved. The highest efficiency of flexible silicon thin film solar cells is 16.3%, the highest efficiency of flexible copper indium gallium selenium solar cells is 20.8%, the highest efficiency of flexible cadmium telluride solar cells is 13.8%, and the highest efficiency of flexible perovskite solar cells is 21.1%.

Moreover, commercial flexible silicon thin film solar cells and flexible copper indium gallium selenium solar cell modules have emerged, demonstrating the enormous development potential of flexible solar cells.

Flexible calcium iron solar cells, as the third-generation new type of solar cells, are currently in the research and development optimization stage. Their conversion efficiency has improved rapidly, and their development prospects are widely recognized, with the potential to unleash huge commercial value.

However, low conversion efficiency and high production costs are still two important factors restricting the development of flexible solar cells. Therefore, developing new flexible substrate materials, developing new processes and structures for battery preparation, and improving the level of equipment manufacturing industry will help improve the conversion efficiency of flexible solar cells, reduce production costs, and promote the industrial development of flexible solar cells.