As a supporting product of photovoltaic modules, the cost of the junction boxes is less than one-tenth of the cost of solar panels, but it is an important component to determine whether the photovoltaic modules can work normally in the end.

Because it can not only transmit the electricity generated by solar panels to external circuits but also be the “bodyguard” of photovoltaic modules. If the junction box is improperly selected, the solar panel can be burned, which will affect the performance of the whole photovoltaic system.

At present, there are many brands of junction boxes in the market, and the product quality is uneven. There are more and more problems in the application of junction boxes in the system. Today, we will take you to have a comprehensive understanding of the junction box from three aspects: the composition, function, quality improvement suggestions, and development direction of the junction box.

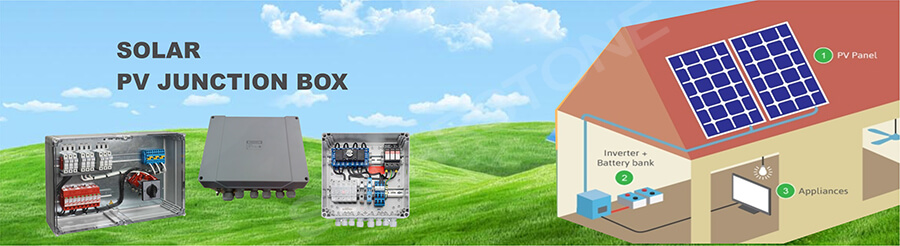

1. Composition and material of junction box

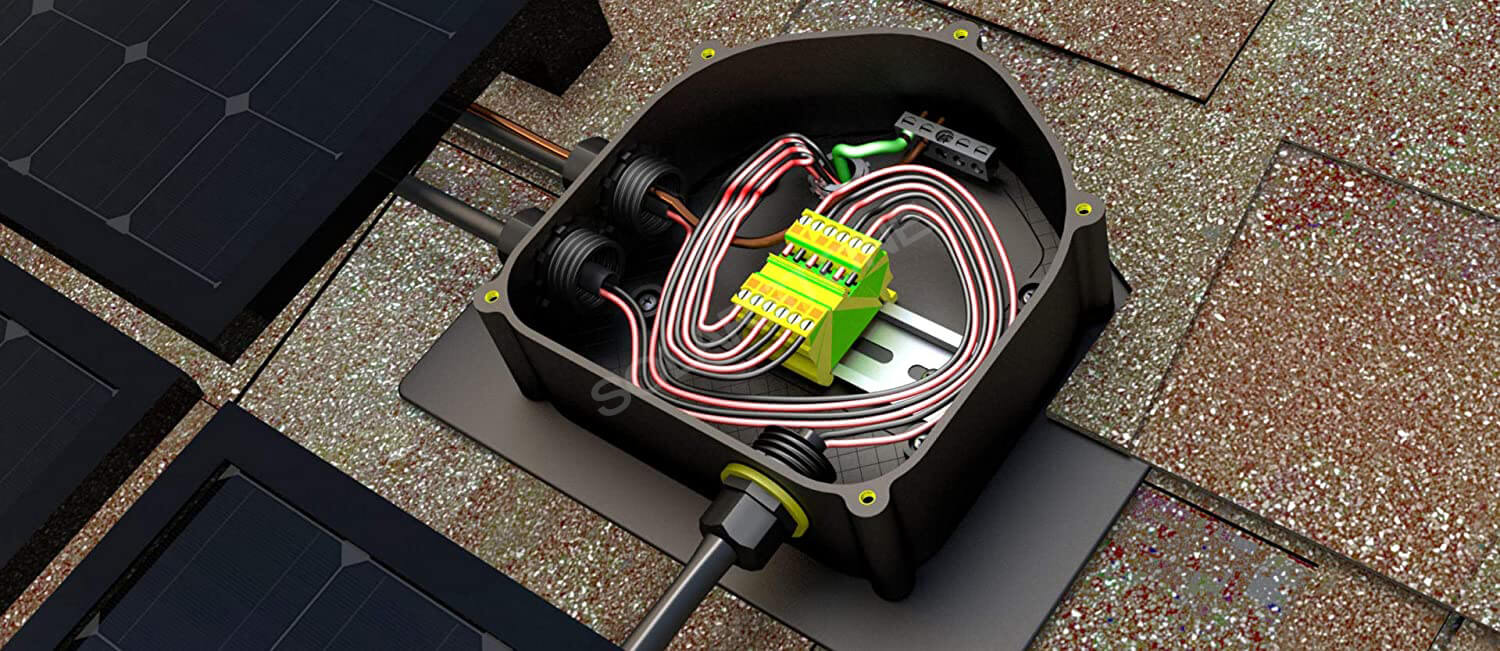

There are various styles of junction boxes, but the basic structure is unchanged, including box body, box cover, connector, wiring terminal, diode, etc. Some junction box manufacturers have designed heat sinks to strengthen the temperature distribution in the box, and some junction box manufacturers have made other detailed designs, but the overall structure has not changed.

A simple junction box requires at least more than ten kinds of materials. The performance and service life of raw materials are related to the quality of the junction box itself. Therefore, the materials of the junction box have been highly concerned by manufacturers and photovoltaic operators.

2. Function of the junction box

The photovoltaic junction box mainly has two functions: the basic function is to connect photovoltaic modules and loads, draw out the current generated by photovoltaic modules and generate power. The additional function is to protect the outgoing line of the photovoltaic module and prevent the hot spot effect.

1) Connect

As a connecting device, the junction box acts as a bridge between photovoltaic modules and control devices such as inverters. Inside the junction box, the current generated by the photovoltaic module is led out and introduced into the electrical equipment through the terminal and connector.

In order to minimize the power loss of the junction box to the photovoltaic module, the conductive material used in the junction box shall have a small resistance, which is smaller than the contact resistance of the bus strip outgoing line.

2) Protect

The protection function of the junction box includes three parts: one is to prevent the hot spot effect through the bypass diode and protect the solar cell and photovoltaic module; Second, through special material sealing design, waterproof and fireproof; The third is to reduce the working temperature of the junction box and the temperature of the bypass diode through special heat dissipation design, so as to reduce the loss of PV module power caused by its leakage current.

3. Quality improvement suggestions and development direction of the junction box

1) Key points for quality improvement of the junction box

The design of separating the box body and the box cover and sealing by the sealing ring is improved to the integrated sealing treatment of crimping the box body and the box cover, so as to strengthen the sealing performance and sealing strength of the whole junction box structure.

According to the current needs of photovoltaic module certification, manufacturing and use, it is recommended to reserve an expansion connection base in the junction box; Assembling diodes of different specifications can change the maximum working current of the junction box at any time;

According to the production process of photovoltaic modules, two installation methods of sealant and potting sealant shall be reserved in the assembly of the junction box.

It is considered to set an air guide valve on the junction box cover to export the heat inside the box body, or adopt sheet metal terminals inside the junction box and add heat sinks to achieve the effect of cooling.

Through a series of tests, study the mutual matching of different types of silica gel and backplane materials of different materials, and provide a complete set of solutions for the installation, use, and matching of junction boxes for photovoltaic module manufacturers.

2) Development direction of the junction box

Junction boxes play a very important role in photovoltaic modules. With the application of the whole photovoltaic market, major junction box manufacturers are working towards providing higher quality junction boxes, such as designing junction boxes with high rated current, high waterproof, excellent heat dissipation, and low resistance.

At the same time, with the continuous development of photovoltaic intelligent monitoring, the intelligent junction box is also the general trend of junction box development in the future. This intelligent junction box can monitor the operation status of each module at any time and has the tracking function of the maximum output point of photovoltaic modules, which can maximize the power generation and meet the requirements of photovoltaic module-level monitoring.