Reducing the cost of photovoltaic kilowatt hour is the focus of current energy strategy. Under the pressure of photovoltaic cost reduction, it has become a trend to promote cost reduction by system efficiency, especially the high efficiency of solar panels, and reduce the investment cost of system end owners.

However, the solar cell technology innovation is facing a bottleneck, perc is close to the peak theoretical efficiency, heterojunction under the current situation that TOPCON and others cannot break through the cost barrier in the short term, in order to achieve higher power and power generation, it has become an industry consensus to pursue a large-scale path, especially to break the cost reduction bottleneck with G12, dilute the production cost at the manufacturing end, reduce the construction cost of system power station and maximize the income.

However, it is unrealistic for solar cells and solar panels to “blindly seek to be large”. In addition to the limitations of auxiliary materials, G12 will be the limit size for industrial application in a long time under the influence of various factors such as size, transportation and weight of solar panels.

What are the advantages of high density encapsulation technology? Compared with traditional solar panels, high-density solar panels can reduce the solar cell spacing and increase the effective light receiving area of a single solar panel, so as to achieve higher power output of solar panels and effectively reduce the BOS investment cost of system end owners.

In addition, based on the optimization of traditional solar panels, high-density solar panels have improved the characteristics of anti attenuation, anti shadow and reducing hot spot effect, which can achieve more power generation gain under the same power and environment, and further reduce the system LOCE.

At present, the mainstream high-density solar panel technologies in the market include overlap welding, round ribbon welding, triangular ribbon welding. Let’s analyze the characteristics of each technology.

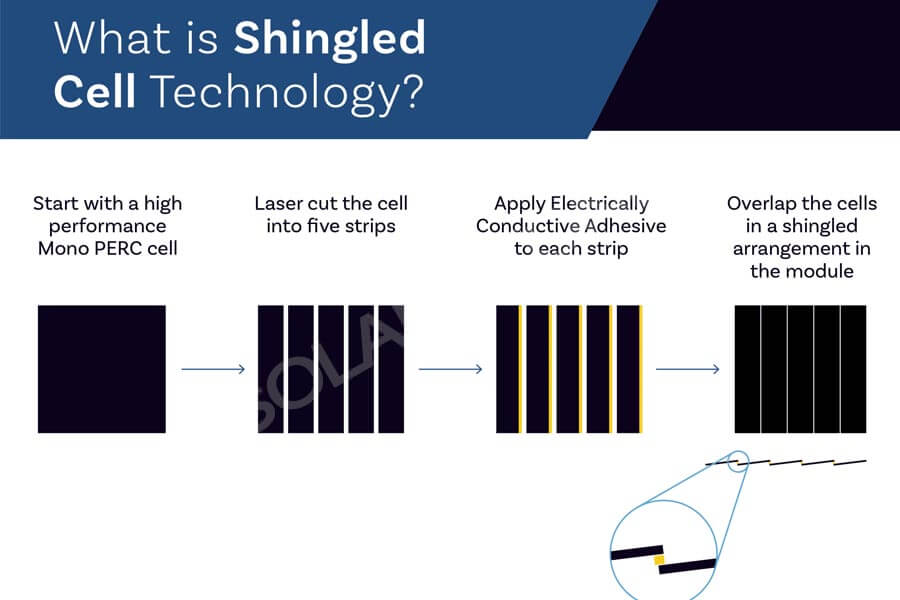

Overlap welding: a revolutionary high-efficiency solar panel encapsulation technology based on traditional solar panel technology.

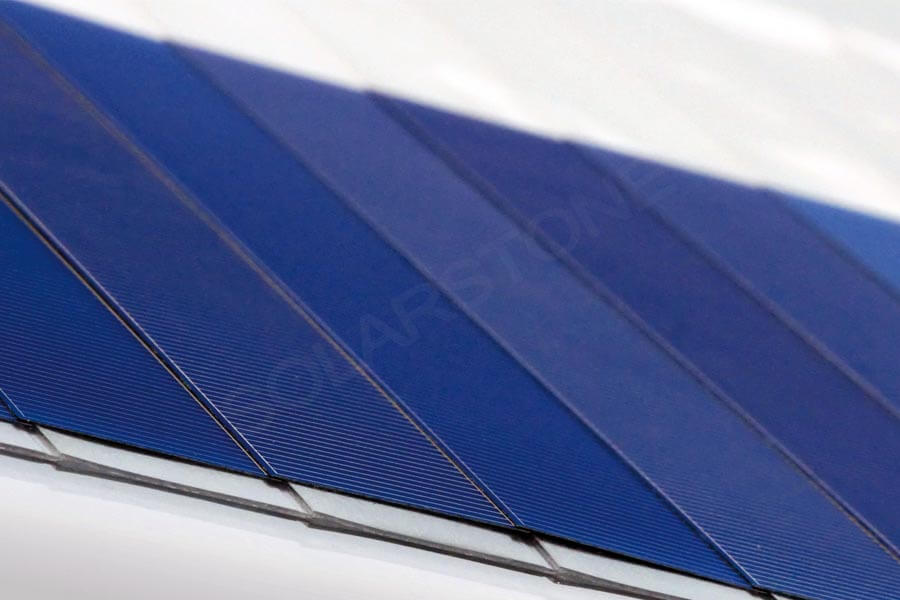

The laminated solar panel uses laser slicing technology to cut the whole solar cell into several small solar cells, and uses conductive adhesive to flexibly connect the small solar cells, which optimizes the solar panel structure, realizes the zero spacing of solar cells, and makes full use of the limited area of solar panels, The same version can place 5% more solar cells than other types of solar panels, effectively improving the light receiving area of solar panels.

Because this process adopts conductive adhesive to realize the laminated interconnection of solar cells, it does not need to follow the traditional solar panels to realize the series connection of circuits through the contact between welding strip metal and silicon substrate, so as to reduce the line loss and effectively reduce the heat loss.

In addition, solar cells are flexibly connected through conductive adhesive, and the stress distribution is uniform, which can not only adapt to thinner silicon wafers and effectively reduce the cost, but also reduce the risk of crack. Small solar cells can limit the impact of crack to a smaller area, even if there is crack power loss. In the circuit design, the laminated solar panel realizes the full parallel circuit, which has better anti shadow, anti attenuation and anti hot spot performance than other types of solar panels.

Round ribbon welding: as a new half solar cell technology, it is an innovation in the traditional half solar cell technology.

Round ribbon welding solar panel uses a special round wire welding belt to “overlap” the adjacent half solar cells at a micro spacing, which greatly reduces the solar cell spacing in the traditional welding process, only 0.2-0.5mm, and realizes high energy density. The round wire welding strip has narrower cross section than the ordinary flat welding strip, which reduces the light shielding of the welding strip to the solar cell.

In addition, the circular side of the welding strip also enhances the reflection of incident light and the secondary refractive index of light of the front cover glass. The introduction of the round welding strip effectively solves the inherent contradiction between the shielding of the main grid and increasing the current collection capacity, It improves the light absorption and utilization of solar cells and increases the power of solar panels.

However, this process still uses the welding belt to realize the “stack” interconnection of solar cells. The technical difficulty lies in the treatment of circular welding strip in the overlapping area of solar cells and the thickness control of the overlapping part. If the thickness of the overlapping part of solar cells cannot be consistent with that of the non-overlapping part, there will be a certain risk of cracking and even debris when the solar panel is laminated.

Moreover, the welding strip itself has strong stress, gaps need to be left between solar cells to release the stress, and there will still be a certain chip spacing in the module packaging, so it is impossible to achieve the limit at high energy density.

At present, China’s top solar panel manufacturers have launched products of this technology type. The degree of technological development is relatively mature and accounts for a large proportion in the market.

Triangular ribbon welding: it is also a new semi solar panel packaging technology.

The triangular welding strip is used on the front of the solar cell and the super flexible flat welding strip is used on the back of the solar cell. Through the double welding strip technology, the micro spacing of adjacent half solar cells can be welded, and the spacing can be reduced to 0.2-0.4mm, realizing high energy density.

The triangular welding strip used in the splicing technology is stereoscopically welded on the front of the solar cell. The reflection ability of the included angle on the near 45o side to the incident light is further improved than that of the circular welding strip, which can make full use of the reflection to increase the light absorption capacity of the battery and increase the power of the solar cell panel.

However, this process needs to be combined with the double welding strip treatment technology. The process is complex and the stability of the equipment is unknown. In terms of product performance, the efficiency is still lower than that of laminated solar panels. In addition, due to the high thickness of the triangular welding strip used on the front of the solar panel, the EVA encapsulated on the front of the solar panel needs to be thickened, so the cost will increase accordingly.

However, due to the use of super flexible welding tape on the back of solar cells, the spacing of solar cells can be reduced compared with stack welding, which is closer to the packaging density of laminated solar panels. At present, patching technology is rarely applied in the industry.

Conclusion:

In conclusion, from the perspective of system revenue, “G12 large size” + “high energy density” is the application and development trend of high-efficiency solar panel technology. In terms of high-density solar panel technology, the core of these technologies is to achieve “high energy density” by reducing the solar cell spacing. Only overlap welding technology can truly achieve zero solar cell spacing and achieve the ultimate high-density encapsulation.