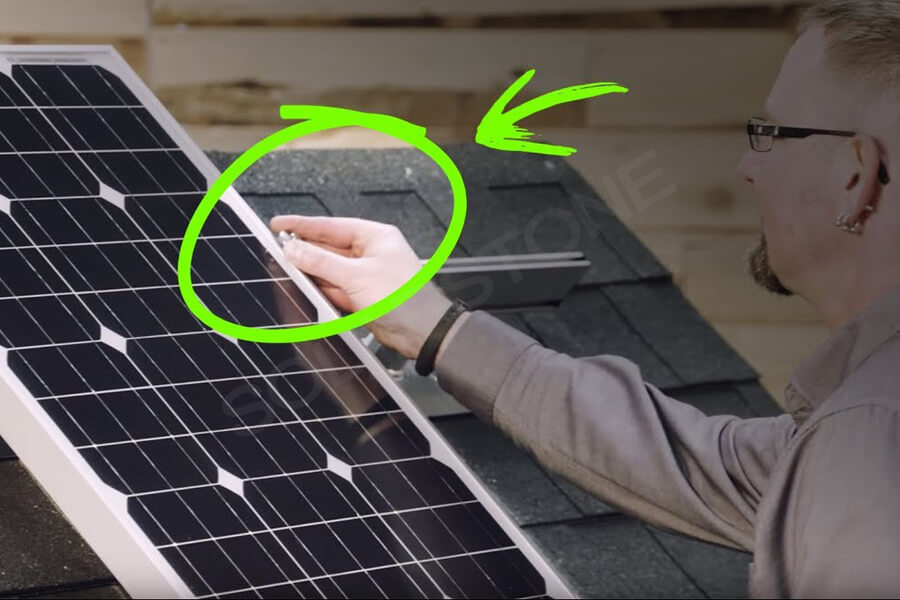

1. Solar cell crack

Causes:

A. The solar cell is caused by an external force during welding or handling.

B. The solar cell is not preheated at low temperature and expands after being suddenly exposed to high temperature in a short time, resulting in cracks.

C. The instantaneous temperature is too high during welding.

Precautions:

a. In the production process, avoid the solar cell from being collided by external forces.

b. In the welding process, the solar cell shall be insulated in advance, and the temperature of the soldering iron shall meet the requirements.

c. El test shall strictly analyze the thin linear black belt on each picture.

d. When there is a crack in the picture, open the backplane and EVA and confirm with a flashlight. Concealed lobes shall be replaced in time.

2. EVA insoluble

Causes:

A. EVA material expired.

B. The design of the heating process of the laminator (such as the low temperature of the laminator, short lamination time, etc.) is unreasonable.

C. The correct process parameters of EVA could not be found out by cross-linking test.

Precautions:

a. Strengthen the improvement of raw material suppliers and raw material inspection.

b. Strictly control the temperature, time, and other important parameters of the laminator.

c. The crosslinking degree test shall be conducted as required, and the crosslinking degree shall be controlled within 85% ± 5%.

d. Different materials from different manufacturers use different process conditions.

3. Bubble

Causes:

A. There is foreign matter in the assembly.

B. EVA expired.

C. Fault of laminator: low vacuum and crack of sealing ring.

D. Laminator parameter setting is abnormal.

E. Residual flux on the surface.

F. Faulty welding of interconnection strip.

Precautions:

a. Improve the workshop production environment and check before lamination.

b. The EVA used shall be within the warranty period, and those that cannot be used up on the same day shall be sealed and stored.

c. Adjust the laminator parameters when large-area bubbles burst.

d. Spot check the laminator for each shift, timely observe the upper and lower vacuum values, timely check the condition of the sealing ring, and do a good job in daily maintenance.

e. EVA from different manufacturers has different lamination parameters, and the process shall be adjusted in time.

f. The use of flux shall be controlled, and the residual surface shall be cleaned with alcohol.

g. The repair of solar cells on the stacking table shall be reduced as much as possible to prevent foreign matters from falling into and eliminate secondary pollution.

h. The management personnel shall confirm the process value set by the laminator every day.

4. Black solar cell

Causes:

A. The positive and negative interconnection bars are short-circuited.

B. Faulty welding of interconnection strip.

C. The diode of the junction box is welded reversely or the wiring is abnormal.

D. The external wiring of the tester is abnormal.

Precautions:

a. Prevent residual solder at the edge of the solar cell during string welding.

b. Prevent false welding when the temperature is low.

c. Focus on the image during the initial measurement.

d. After the final test, the abnormal frame shall be folded and replaced.

e. Check the diode welding and lead welding of the junction box in case of black sheet.

f. Check the external wiring of the tester.

5. Poor tin slag

Causes:

A. Residual tin slag during welding.

B. Tin slag is stuck on the bottom plate.

C. There is a lot of tin residue on the soldering iron head.

D. Welding shall be carried out on the solar modules during film replacement.

Precautions:

a. During the welding operation, the tin pile on the soldering iron head shall be cleaned in time to prevent tin slag from falling.

b. Clean the bottom plate in time to eliminate tin residue.

c. Do not replace welded solar cells on stacked solar panels.

d. After series welding, timely check whether there is tin residue on the solar cell.

e. After the short circuit of two grids caused by tin slag, hot spots will be generated, which will affect the service life of the module. Abnormal solar cells must be replaced.

6. Foreign matter

Causes:

A. Foreign matters stick to the solar cell during welding.

B. Weld the dirt on the base plate.

C. The turnover box for welding is dirty.

D. When stacking, the glass base plate and EVA well adhere with dirt.

E. Hair, dirt, etc. fall on the solar cell during operation.

F. Secondary pollution when replacing the solar cell due to poor initial measurement.

G. The backplate wire falls into the assembly and is polluted.

Precautions:

a. Welding and stacking personnel shall dress according to regulations and wrap their hair in clean hats.

b. Do not touch the solar cell by hand.

c. Welding personnel are forbidden to stick adhesive tape on solar cells.

d. The stacking personnel shall pay attention to check the pollution of glass base plate and EVA during operation.

e. The welding table, welding base plate, welding turnover box, and stacking table shall be cleaned regularly.

f. The welding room and laminated area shall be cleaned regularly with a wet dust mop to keep the ground free of foreign matters.

g. The El workbench shall be cleaned regularly to prevent foreign matter pollution when the solar cell is poor in the secondary inspection.

h. Personnel clean clothes shall be cleaned regularly.

7. Poor spacing

Causes:

A. The poor spacing between pieces is caused by the operation during series welding.

B. Poor string spacing is caused by stacking operation.

C. The abnormal dimension from the edge is caused by stacking operation.

D. Improper use of formwork for welding.

Precautions:

a. The welding personnel shall pay attention to the placement of solar cells on the base plate template during series welding.

b. When placing the string of solar cells, the stacking personnel shall place them according to the positioning size of the template, measure the distance with a ruler in time, and then stick the position of solar cells with adhesive tape.

c. EVA is abnormal, causing displacement of the solar cells during lamination.

d. Correctly use the welding head and tail positioning template. Different manufacturers of solar cells use different specifications of positioning templates.

e. Daily manage the positioning templates of different manufacturers to prevent mixing.

8. Broken solar cell

Causes:

A. Single string welding is too heavy, resulting in.

B. There are spot tin accumulation, welding beads, and false welding during interconnection strip welding, resulting in layer fracturing.

C. When the laminated and laminating personnel lift the laminated solar cells, the personnel touch and press the solar cells with their hands.

D. The quality of the solar cell itself is caused by cracks.

E. It is caused by high pressure in the pressurization stage of the laminator.

F. EVA is uneven (serious bulge).

G. The hand gesture of the laminating personnel when covering the laminated cloth is incorrect.

Precautions:

a. The stacking and laminating personnel shall not touch the solar cells on the side when lifting the stacked solar cells.

b. When lifting the stacked solar cells, the laminating and laminating personnel shall prevent them from touching the crossbar on the trolley.

c. The welding personnel shall prevent the abnormal phenomena of surfacing, welding beads, and false welding during welding.

d. During the initial survey, carefully analyze each picture to prevent hidden cracks from flowing into the lamination group.

9. False welding and over welding

Causes:

A. The welding temperature is too low and the bottom plate temperature is low.

B. Too little flux.

C. Excessive speed will lead to false welding.

D. Too high welding temperature or too long welding time will lead to over welding.

Precautions:

a. Ensure that the welding temperature parameter is set and checked regularly. The welding time is 3-4 seconds.

b. The temperature of soldering iron, welding time, and use of flux shall be ensured during the repair.

c. Strengthen El inspection.

d. Regularly manage the soaking solution and time of the interconnection strip.

10. Dark solar cell

Causes:

The power gear is confused due to raw materials.

Precautions:

a. Strengthen the inspection of incoming materials; Improve the sampling proportion and feed back to the supplier in time.

b. During the production process, the confusion of power gear shall be controlled (especially the process of replacing a single chip).

11. Poor frame

Causes:

A. There are problems with the incoming materials.

B. Caused by impact during processing.

C. The blade and file are scratched during cleaning.

Precautions:

a. The operator shall have self-inspection ability for the materials used.

b. Pay attention to the operation in the framing process and often check the effect after framing.

c. Hold the solar module firmly when lifting it, and do not do as you like.

d. When cleaning, the blade and file shall be careful to touch the aluminum profile.

e. In particular, the size of the profile and the internal teeth on the long side are too shallow.

f. The technician shall manage and confirm the size after framing.

12. Rubber bubble

Causes:

A. Glue bubbles are mainly caused by bubbles in collagen material or unstable air pressure of air guns.

B. The gap is mainly caused by the non-standard glue application of employees.

Precautions:

a. Strengthen personnel skill training and enhance self-inspection awareness.

b. The gluing method of personnel shall be standardized.

c. The cleaning personnel shall conduct a strict inspection.

d. Pay attention to adjusting the air gun pressure.