Why is there a deviation in the color of solar panels? This question once puzzled not only photovoltaic people, but also many users who installed photovoltaic power generation systems. I don’t know whether it will affect the use. Next, we will answer this question for you. Why are there color differences in photovoltaic cells?

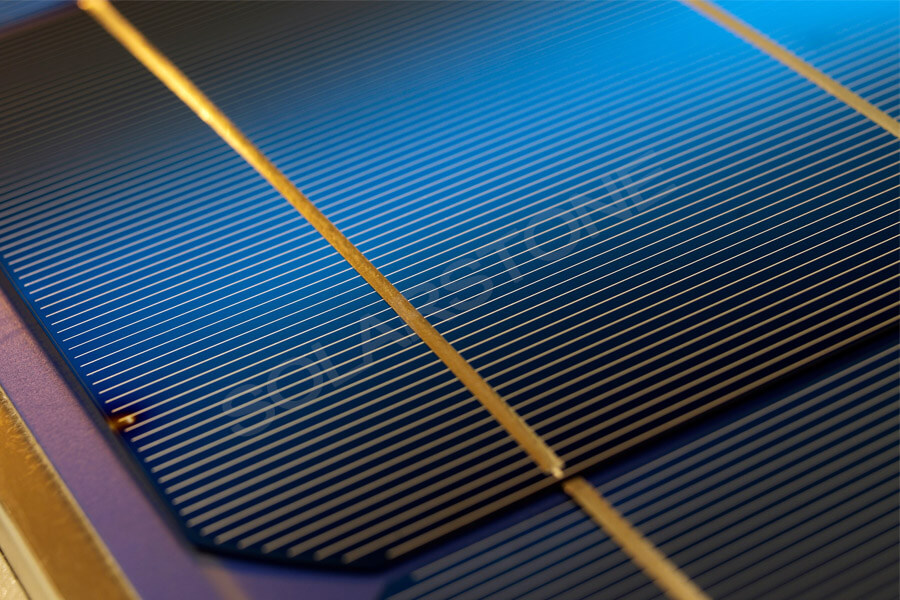

In fact, the color of solar cells is mainly affected by velvet, including flower chips, red chips.

The red sheet is mainly caused by the low corrosion of cashmere making. If the flocking corrosion is less than 3, the damaged layer of the silicon wafer will not be removed completely, resulting in the overall red color after PE coating.

The so-called flower chip is caused by the excessive corrosion of cashmere making. Generally speaking, when the corrosion of cashmere making is higher than 4.5, the silicon chip is equivalent to polishing treatment. The battery chip after the coating is bright and the grain boundary is obvious.

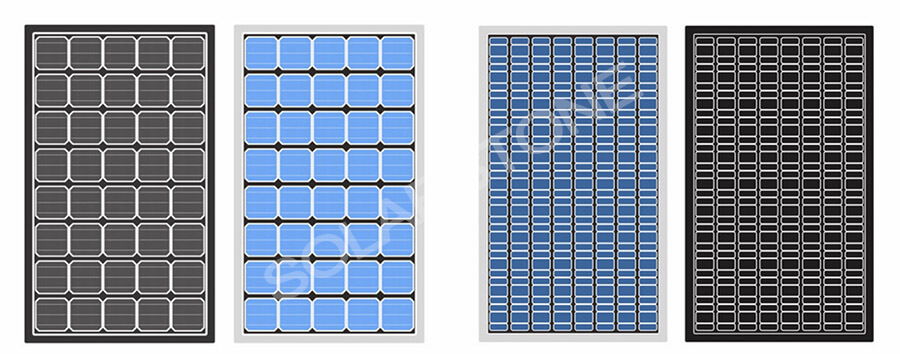

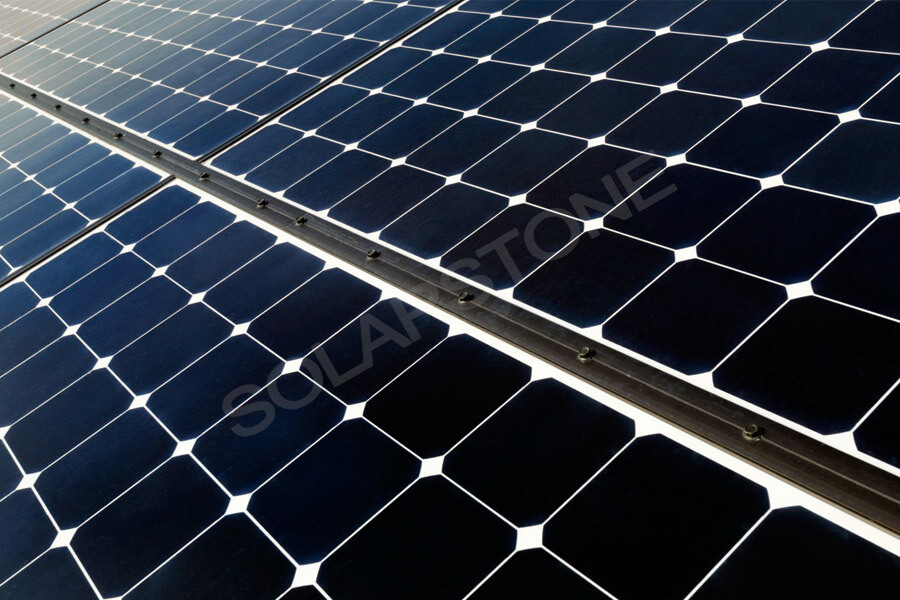

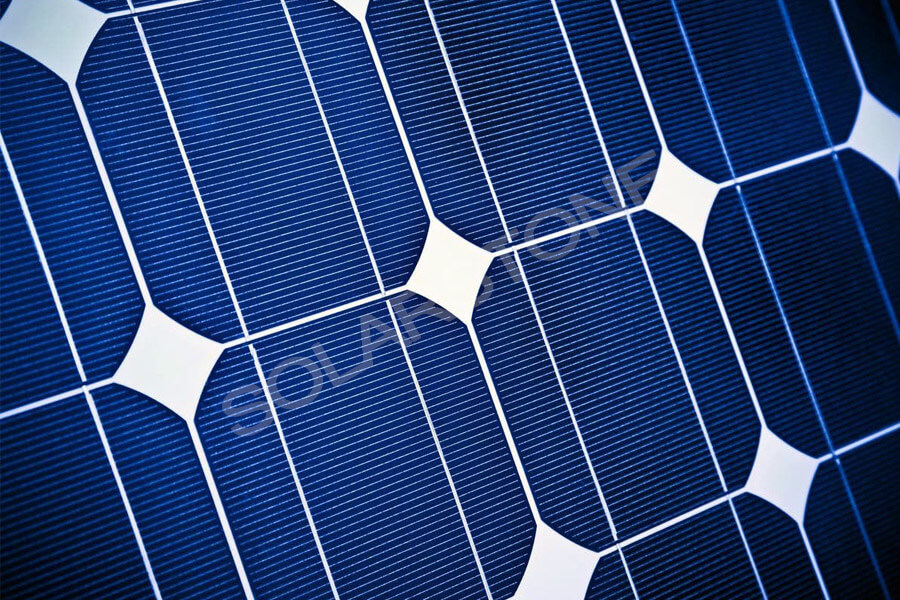

The common color deviation is polysilicon cell. For polysilicon cells, dark blue is the most common color, and monocrystalline silicon is black.

Through process adjustment, the above color deviation can be effectively solved. For users, the criteria for evaluating the quality of solar panels are as follows:

The overall appearance of solar panel

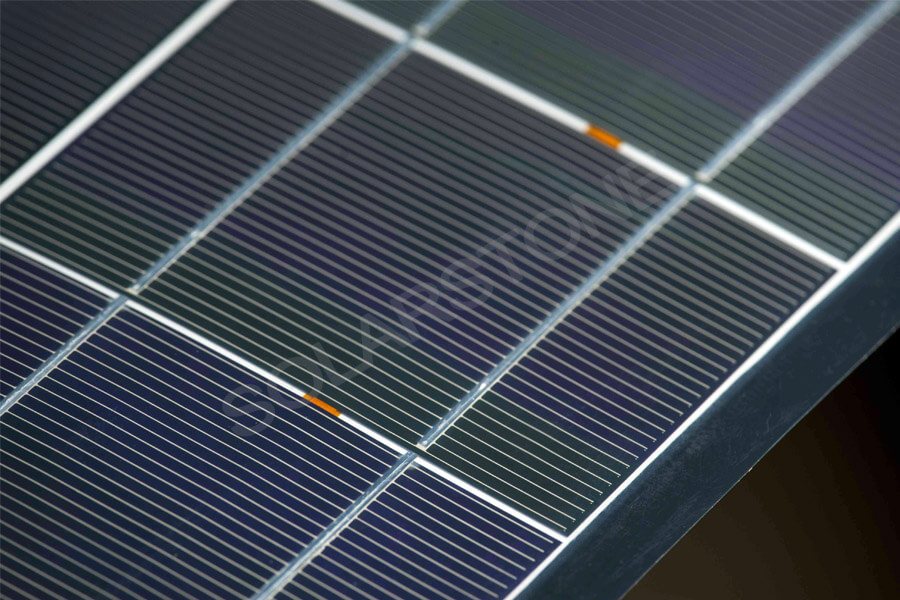

1. On the whole, the surface color of solar cells in the same batch of solar panels shall be uniform without obvious color difference, grid breaking, defect damage, solder joint oxidation spots, etc.

2. Each string of solar cells in the solar panel shall be welded with the interconnection strip in order without deviation, the spacing between the battery strings shall be uniform without obvious deviation, and there shall be no tin accumulation and oxidation on the surface of the welding strip.

3. There is no bubble or delamination in the sealing layer of the solar panel, the layer is clear and transparent, and there is no dirt and mottled inside.

4. The aluminum frame of the solar panel shall be clean without corrosion spots, and the interface shall be compact without obvious gaps, sharp and burrs.

5. The edge sealing of silica gel shall be uniform without local glue stacking.

6. The junction box shall be clearly marked, firmly bonded, and the binding buckle shall be intact and firm.

Low iron tempered suede glass

At present, conventional solar panels are made of low iron tempered suede glass. The glass surface must be clean and tidy without a scratch, indentation, wrinkle, rainbow, crack, indelible dirt, opening bubble and other adverse factors. For coated glass, it is also necessary to squint at the glass surface, and there shall be no colorful light, embossing print, grease fingerprint and other contamination.

Solar cell

The appearance of class A solar cell must meet the following standards: no edge collapse, angle collapse, notch, virtual printing, slurry leakage, color spot, watermark, fingerprint, oil stain, scratch, crack, oxidation, yellowing and other defects; No obvious color difference;

Flatback aluminum; There shall be no aluminum beads, aluminum bags, aluminum thorns and folds.

Yellowing and oxidation of grid lines are not allowed; The main grid line is not allowed to break;

The printing offset of the battery is not allowed, and the printing offset is less than 0.5mm.

Solar panel backplane

The backplate surface is clean, flat, clean and colorless. The surface shall be free of foreign matters, dirt, watermarks, folds, bumps, bulges and scratches; There is no obvious gap between the backplate and the glass edge.

Junction box

The junction box shall have indelible marks: product model, manufacturing material, voltage grade, waterproof grade, output terminal polarity and warning mark;

The connection between the junction box and the cable shall be reliable without falling off buckles and the buckles connecting the upper and lower shells shall be intact and firm;

The silica gel of the junction box base shall be firmly bonded with the backplate without warping and visible gap;

The bus bar is led out from the backplate, beautiful and without distortion, and the two adjacent bus bars shall not contact each other;

The connector terminals are marked with significant positive and negative polarity; The male and female connectors are in good contact and have good self-locking performance.

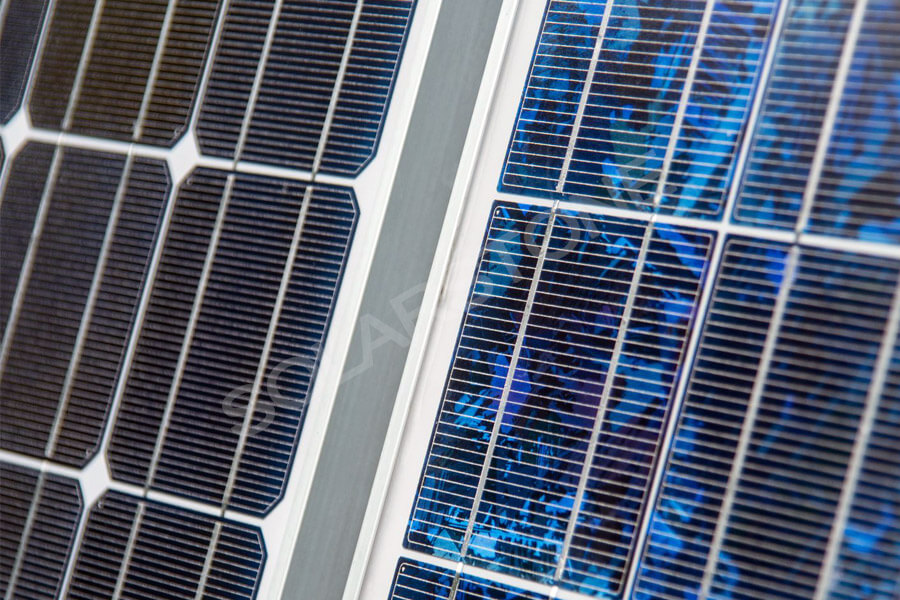

Aluminum frame

The aluminum frame is usually aluminum alloy with an anodized surface;

Appearance: the frame surface shall be clean and flat without damage, color difference, scratch, obvious dirt, silicone residue, etc; Complete wiring holes and mounting holes with correct length and position;

Wireless injuries, scratches, bumps (including corners), mechanical lines, craters, pits, peeling, corrosion, bubbles, watermarks, mimeographs, and dirt; No burr on the edge;

At present, the good mechanical load performance of photovoltaic modules mainly comes from the support and protection of the frame. At present, the frame width commonly seen in the market is 35-40mm. For projects or regions that need to test the load performance, higher frame width (45, 50mm) should be pursued for protection.

In conclusion, for the color deviation of solar panels, a more reasonable judgment needs to be made in combination with the evaluation standards to determine whether there is a quality problem.