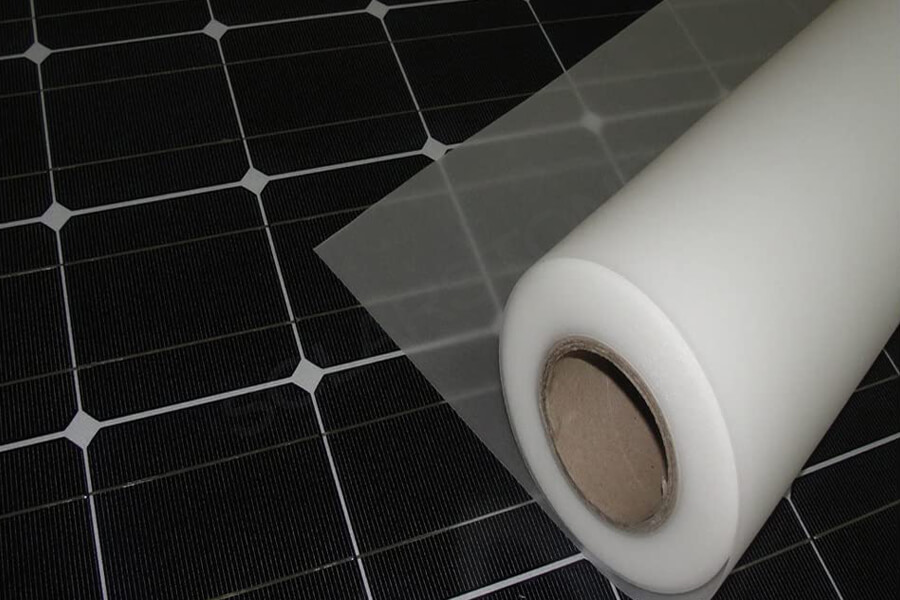

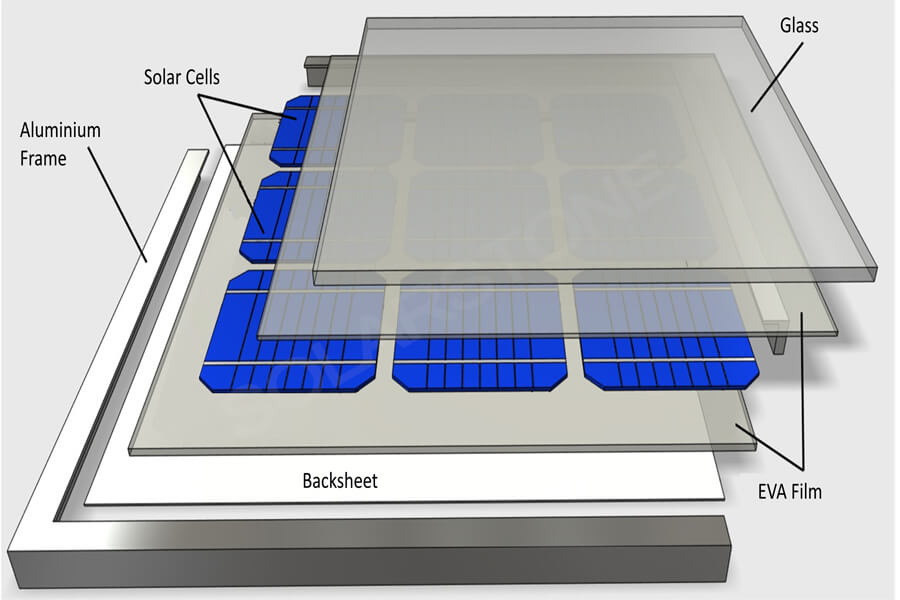

The invention and application of photovoltaic modules are an important part of humanity’s opening up of the new energy era. EVA film is one of the most critical packaging materials in the production process of photovoltaic modules. It can lay the top and bottom covers of solar cells in the middle, playing a role in protecting solar cells.

What is EVA film?

EVA is a thermosetting adhesive film used in the middle of laminated glass. It is a functional film made by adding crosslinking agents, coupling agents, and UV resistant agents to a resin based on ethylene vinyl acetate copolymer.

Due to its superior adhesion, durability, and optical properties, EVA film is increasingly being used in current modules and various optical products.

Characteristics of EVA film

EVA is a solid at room temperature, without viscosity and poor transparency. When heated to a certain temperature, EVA will melt and bond to the object in contact with it. EVA used for solar cell packaging is a specially designed thermosetting hot melt adhesive, which generates cross-linking reaction during heating and melting.

When the temperature is low, the rate of crosslinking reaction occurs slowly, and the time required to complete curing is longer. Conversely, the time required is shorter.

Therefore, it is necessary to choose an appropriate lamination temperature to enable EVA to obtain fluidity in the melt and undergo curing reaction. As the reaction proceeds, the degree of crosslinking increases, and EVA loses its fluidity, playing a role in encapsulation.

EVA film can bond the battery, glass, and backplate together under certain temperature and pressure, providing strong mechanical protection and effectively protecting the battery from external environmental erosion. Therefore, the crosslinking degree of EVA film is particularly important.