BIPV, also known as Building Integrated PV, is the integration of photovoltaic buildings. PV stands for Photovoltage. BIPV technology is a technology that integrates solar power (photovoltaic) products into buildings.

In modern society, people’s pursuit of a comfortable building environment is increasing, leading to an increasing energy consumption of building heating and air conditioning.

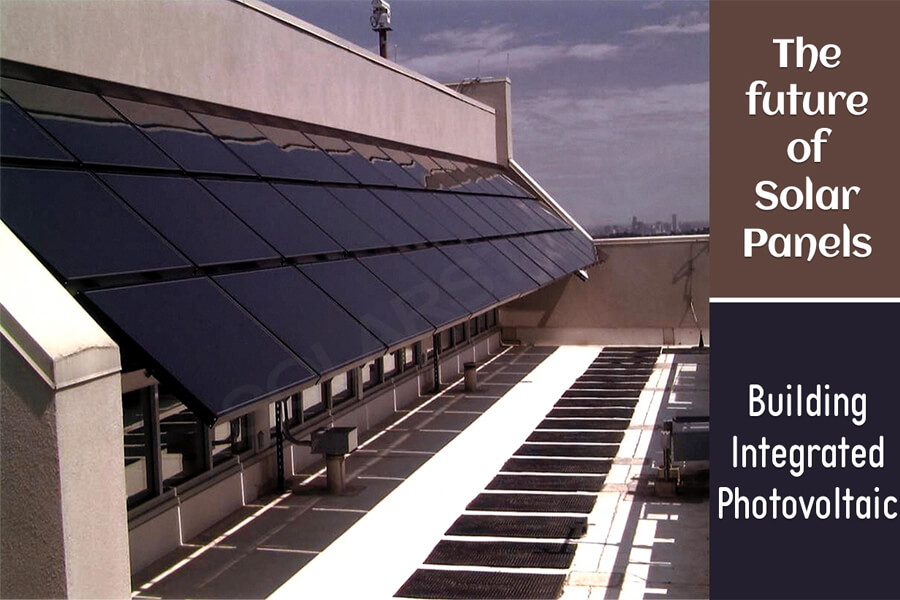

BIPV has various forms of building photovoltaics, and it can be said that BIPV is suitable for most buildings, such as flat roofs, sloping roofs, curtain walls, ceilings, and other forms that can be installed.

Safety performance

BIPV modules not only need to meet the performance requirements of photovoltaic modules, but also meet the requirements of the three property experiments of curtain walls and building safety performance.

Therefore, they need to have higher mechanical properties than ordinary modules and adopt different structural methods. The mechanical performance requirements for its glass may be completely different in different locations, floor heights, and installation methods.

The double glass photovoltaic modules used in BIPV buildings are composed of two tempered glass sheets, with a composite layer composed of PVB film composite solar cells in the middle. The cells are composed of a whole component consisting of wire series and parallel collection of lead ends.

The thickness of tempered glass is determined through strict mechanical calculations in accordance with national building and curtain wall regulations. The PVB film in the middle of the component has good adhesion, toughness, and elasticity, which has the function of absorbing impact and can prevent the penetration of impact objects.

Even if the glass is damaged, the fragments will firmly adhere to the PVB film and will not fall off and cause harm to people, thereby minimizing the harm caused and improving the safety performance of the building.

BIPV photovoltaic building testing solution: Integrated photovoltaic building (BIPV) is the integration of photovoltaic (PV) into building envelope structures. Photovoltaic modules have a dual function as building skins: replacing traditional building envelope materials and generators.

By using BIPV systems as both building envelope materials and generators, they can save material and electricity costs, reduce the use of fossil fuels and emissions of ozone depleting gases, and add architectural fun to buildings.

Easy to install

The BIPV project is a close integration of photovoltaic modules and glass curtain walls. Since the development of curtain walls in China for thirty years, various forms of curtain walls have developed mature design and installation technologies.

The construction method of component curtain wall is flexible, the main structure has strong adaptability, and the technology is mature, making it the most commonly used structural form at present. The unit type curtain wall is processed and manufactured in the factory, which facilitates industrial production, reduces labor costs, controls unit quality, shortens the construction period, and brings significant economic benefits to the owner.

The double-layer ventilation curtain wall system has advantages such as ventilation, heat insulation and sound insulation, energy conservation and environmental protection, and can improve the heat dissipation of BIPV components, reduce the temperature of battery cells, reduce the efficiency loss of components, and reduce the transfer of heat to the indoor environment.

In brief, BIPV building is to replace ordinary tempered glass with BIPV PV modules, and its structural form is basically similar to that of traditional glass curtain walls. This provides a strong technical foundation and advantages for the installation of BIPV photovoltaic modules, which can fully meet the requirements of convenient installation.

Long lifespan

The adhesive used for packaging ordinary photovoltaic modules is generally EVA. Due to its weak anti-aging performance and service life of less than 50 years, EVA cannot have the same service life as the building, and its yellowing will affect the beauty of the building and the power generation of the system.

PVB film has the characteristics of transparency, heat resistance, cold resistance, moisture resistance, high mechanical strength, and has been widely used in the production of laminated glass for construction.

The domestic regulations for glass curtain walls also clearly state the application of PVB. The use of PVB instead of EVA in BIPV photovoltaic modules can achieve a longer service life.

In addition, in the BIPV system, selecting photovoltaic dedicated wires (double-layer cross-linked polyethylene tinned copper wires), selecting larger wire diameters, and selecting high-performance connectors and other equipment can extend the service life of the BIPV photovoltaic system.