In the manufacturing process of photovoltaic cells, the crosslinking degree of EVA layer is an important factor determining its performance. The EVA layer, as an encapsulation material, not only protects the photovoltaic cell from external environmental influences, but also ensures the mechanical stability of the entire photovoltaic module.

The superior adhesion, durability, and optical properties of EVA layer make it increasingly widely used in photovoltaic modules and various optical products.

What is EVA material?

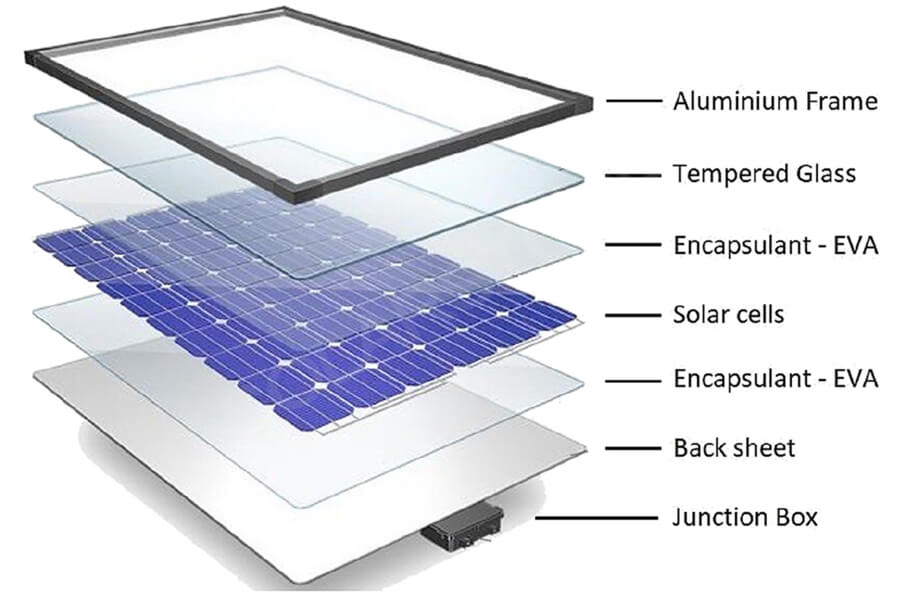

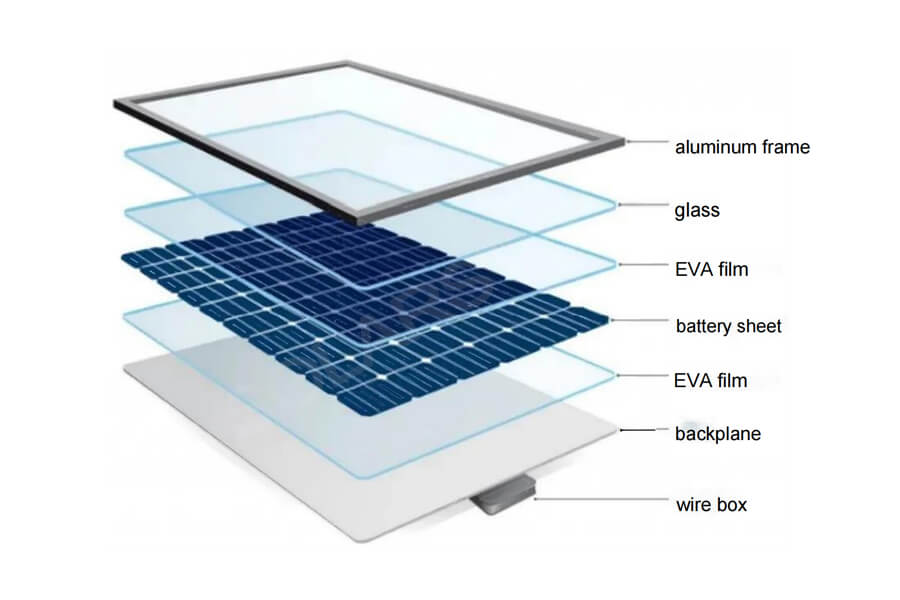

EVA is the most important material in the packaging of solar cells. It is a hot melt adhesive film that is non sticky at room temperature but has anti adhesion properties. After certain conditions of hot pressing, it undergoes melt bonding and cross-linking solidification, encapsulating the solar cell string with a “top cover and bottom pad”.

On the one hand, the cured EVA can withstand atmospheric changes and has elasticity, and is bonded together with the upper protective material glass and the lower protective material backplate TPT; On the other hand, after bonding with glass, it can improve the transmittance of the glass, play a role in increasing transparency, and have a gain effect on the output of solar modules. It has achieved satisfactory results in solar cell packaging and outdoor use.

What is the crosslinking degree of EVA?

Crosslinking degree refers to the mass ratio of linear molecules that crosslink into network like molecules when EVA film is heated. When laminating solar modules, when the heating temperature of the laminating machine reaches the decomposition temperature of the crosslinking agent, the peroxide bond in the crosslinking agent breaks to form peroxide free radicals RO -, which are easily combined with the H of the alkyl group on the EVA branch. After the two alkyl active groups combine, cross-linked EVA is formed.

The degree of cross-linking determines the cohesive strength of EVA film and affects the peel strength between EVA film and backing glass. The cross-linking degree detection data will directly reflect the reliability of solar module packaging, thereby determining the quality of solar modules.

What are the factors that affect the crosslinking degree of EVA?

The amount of crosslinking agent added: An increase in the amount of crosslinking agent added will increase the degree of crosslinking, but too much can easily cause aging and yellowing; If too little is added, the degree of crosslinking is too low, and the bond strength and anti-aging ability will also be affected. Experiments show that 75% -80% is the best.

Laminated temperature: The laminating temperature directly affects the crosslinking degree of EVA. If the laminating temperature is too low, the cross-linking degree may be insufficient, which may cause the solar cells to shift or even break. On the contrary, excessive lamination temperature can cause EVA to age and turn yellow, affecting the service life of solar modules.

Lamination retention time: The lamination retention time also affects the crosslinking degree of EVA. If the holding time is too short, the cross-linking degree may be insufficient; Excessive holding time may lead to high crosslinking degree.