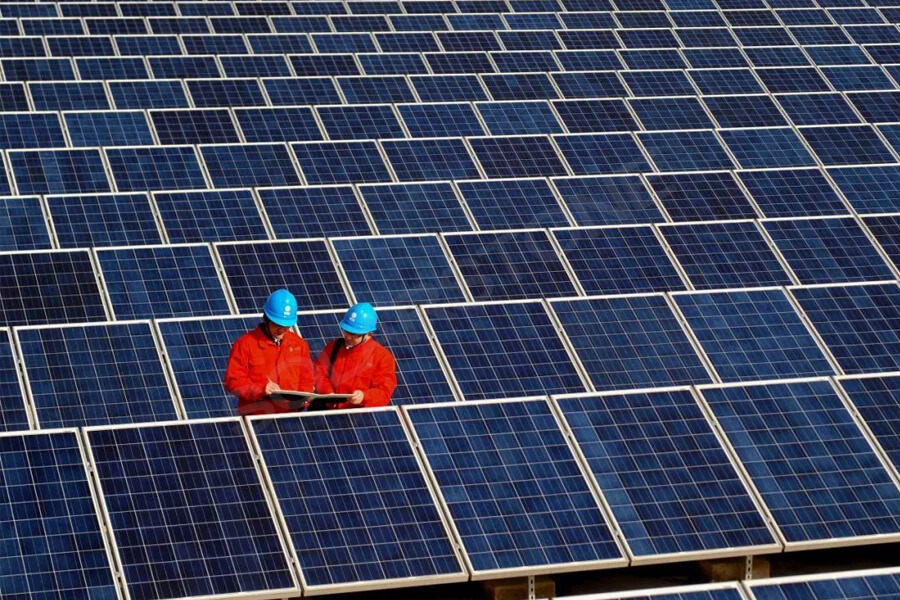

Generally speaking, the common problems of photovoltaic modules include hot spots, cracks, and functional degradation. This type of problem is often hidden inside the solar panel and is not easy to detect.

It is only exposed after the solar panel has been in operation for a period of time, and is usually difficult to identify when the solar panel enters the site for acceptance, requiring the use of professional equipment for testing. This leads to being passive in discovering problems and having to wait for them to come to our doorstep.

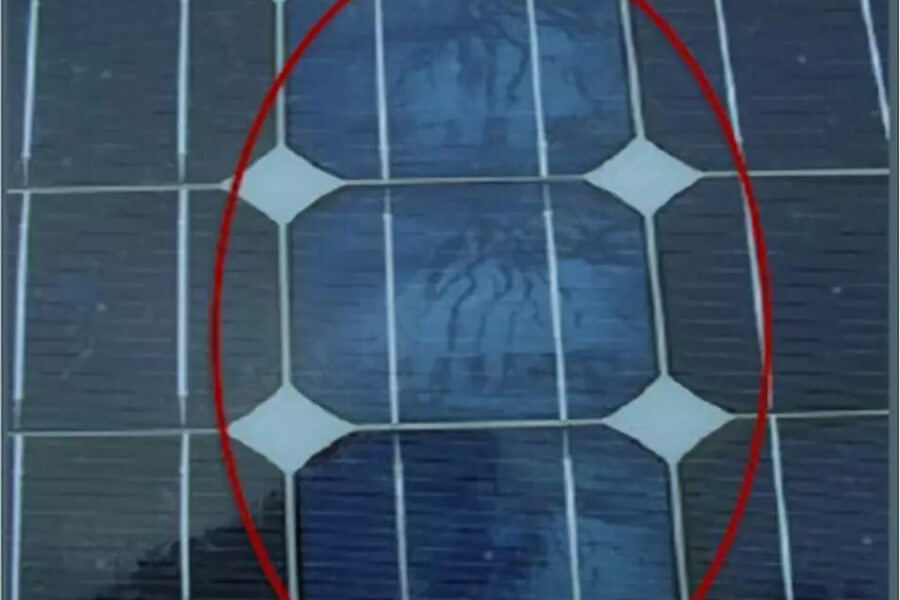

Causes and detection methods of hot spot formation

The “hot spot effect” of a component refers to the phenomenon where some solar cells of a photovoltaic module are blocked from working under sunlight, resulting in uneven heating on the surface of the module.

The covered part heats up much higher than the uncovered part, resulting in a temperature difference on the surface of the module and causing burnt out dark spots on the solar cells due to excessive temperature.

Internal resistance and the dark current of the solar cell itself are two internal factors that form photovoltaic hot spots. Generally, before being put into use, hot spot durability tests are conducted to test whether the solar cell panel can be used for a long time under specified conditions.

Infrared thermal imagers can be used for detection, and thermal imaging technology can be used to identify the temperature and distribution of the hot plate.

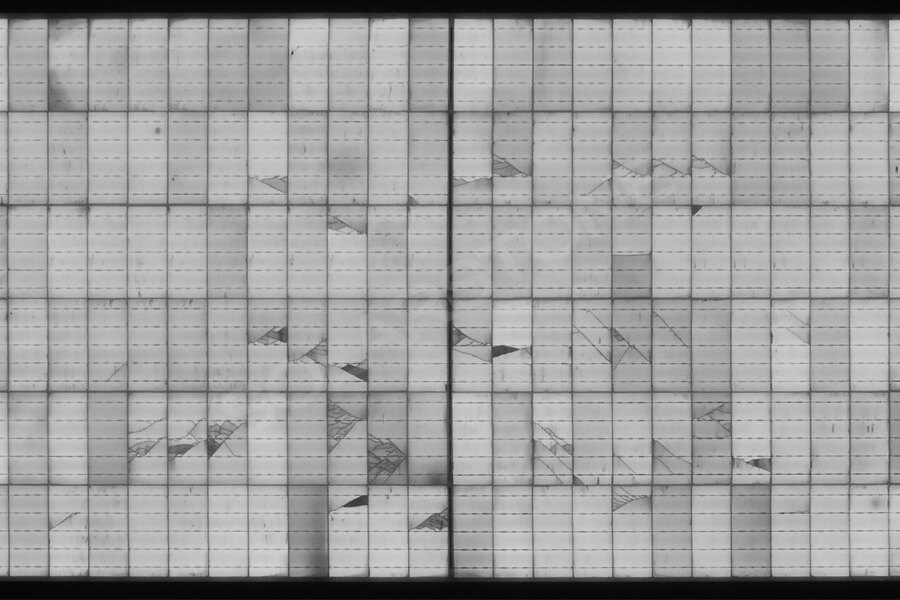

Causes and detection methods of hidden cracks

Hidden cracks refer to small cracks that appear in solar cells, caused by a combination of multiple factors. They accelerate the attenuation of solar cell power, affect the normal service life of components, and may also expand under mechanical loads, leading to open circuit damage and hot spot effect.

In addition, severe shaking during transportation and reshipment can also cause hidden cracks in solar cells. EL detectors can be used for inspection to obtain and determine the defects of components.

Power attenuation classification and detection methods

The phenomenon where the output power of a component gradually decreases as the illumination time increases. The attenuation phenomenon of general photovoltaic modules can be divided into three categories.

One is the power attenuation caused by destructive factors, which can be controlled. For example, strengthening the control of module unloading, inversion, and installation can reduce the probability of hidden cracking and fragmentation of battery modules;

The second is the initial photoinduced attenuation of the component;

The third is aging attenuation, and the latter two types of situations are problems that occur during the production process. Inspection can be completed through the I-V characteristic curve tester to reduce defects in process production.