Definition of photovoltaic modules

1. With packaging and internal connections

2. Can provide separate DC output

3. Photovoltaic cell combination device with minimum indivisibility

Why do we need to manufacture photovoltaic modules? Can’t photovoltaic cells be used directly?

1. Electrodes are easily oxidized when exposed to air.

2. The power of a single crystalline silicon photovoltaic cell is low, with a voltage of only about 0.5v.

3. The thickness is too thin, easy to break, and difficult to handle.

4. Poor weather resistance and fast decay of photovoltaic cells.

Component classification

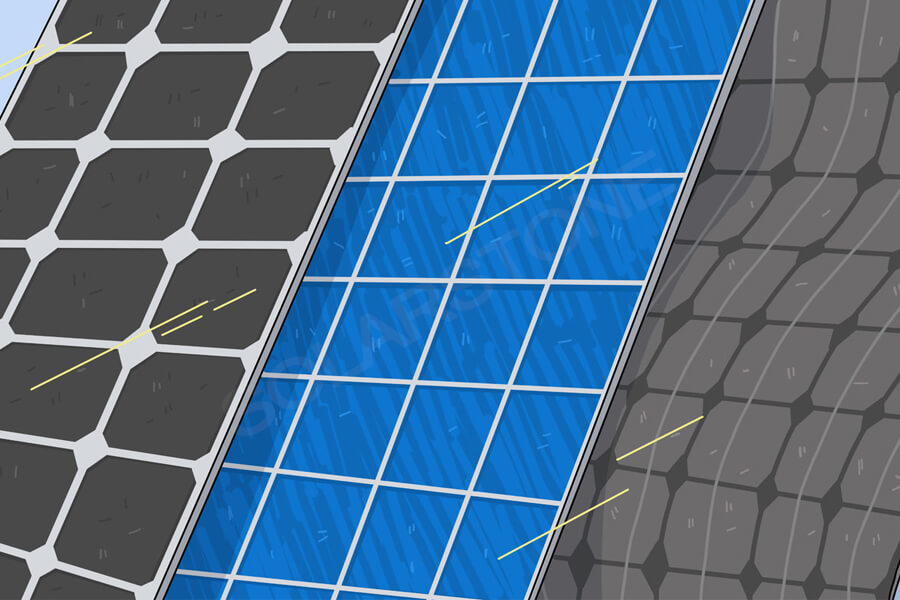

1. Classification by solar cell type

Crystalline silicon (single or polycrystalline silicon) solar photovoltaic modules

Amorphous silicon thin film solar photovoltaic modules

Gallium arsenide photovoltaic modules, etc;

2. Classification by packaging materials and processes

Epoxy resin encapsulated solar panels

Laminated packaged solar cell modules

3. Classification by purpose

Ordinary solar photovoltaic modules

Building material solar photovoltaic modules

Among them, building materials solar photovoltaic modules are further divided into single-sided glass transparent photovoltaic modules, double-sided laminated glass photovoltaic modules, and double-sided hollow glass photovoltaic modules

Common issues with components

1. The surface of photovoltaic modules is dirty

2. Photovoltaic cells have color differences

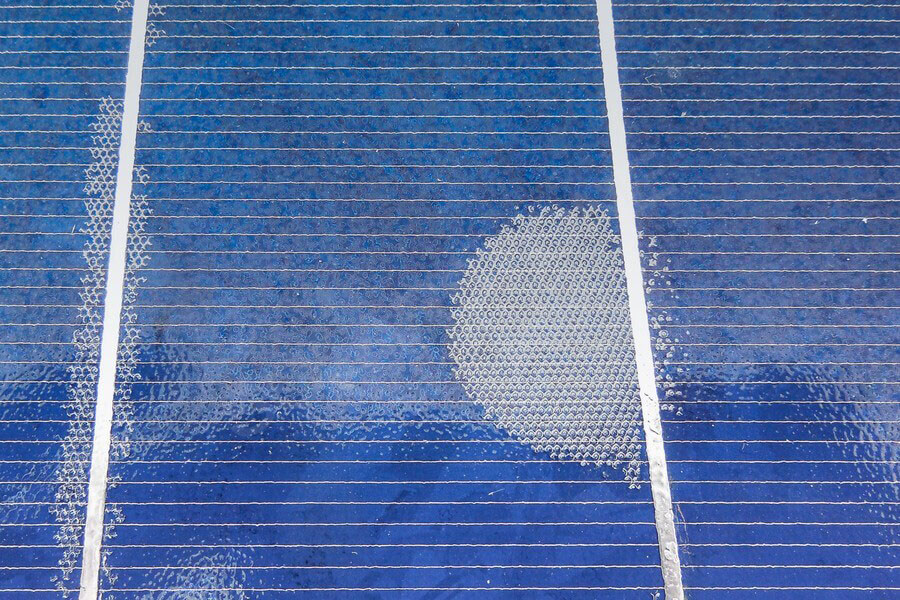

3. Photovoltaic modules with bubbles and EVA delamination

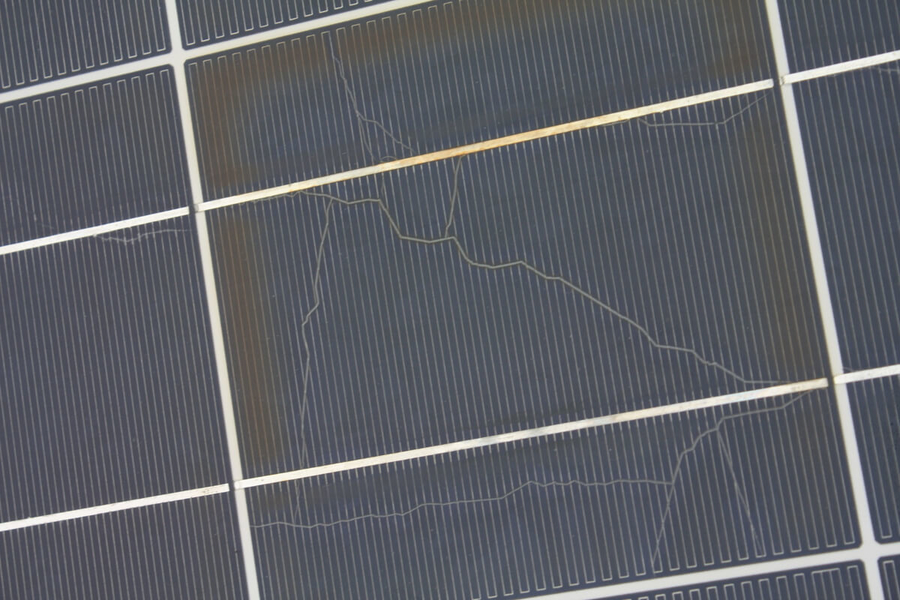

4. Photovoltaic module fragmentation

5. Other quality issues

Common problems, causes, impacts, and measures of photovoltaic modules

Causes of reticular fissures

1. Photovoltaic cells are subjected to external forces during welding or transportation.

2. Photovoltaic cells suddenly experience high temperatures in a short period of time without preheating at low temperatures

cracking caused by expansion after heating.

Impact of photovoltaic modules:

1. Mesh cracks can affect the power attenuation of photovoltaic modules.

2. The long-term appearance of mesh cracks, such as fragments and hot spots, directly affects the performance of photovoltaic modules.

Preventive measures:

1. Avoid excessive impact of external forces on photovoltaic cells during the production process.

2. During the welding process, the photovoltaic cells should be insulated in advance (manual welding), and the soldering iron temperature should meet the requirements.

3. EL testing requires strict inspection requirements.

Reasons for EVA delamination

1. Unqualified crosslinking degree (such as low temperature of laminating machine, short lamination time, etc.)

2. Foreign objects on the surface of raw materials such as EVA, glass, and backboard.

3. The uneven composition of EVA raw materials (such as ethylene and vinyl acetate) leads to the inability to dissolve at normal temperature, resulting in delamination.

4. Excessive amount of flux, resulting in delamination of the main grid line when exposed to high temperatures for a long time outside.

Impact of photovoltaic modules:

1. A small delamination area affects the high-power failure of photovoltaic modules. When the delamination area is large, it directly leads to component failure and scrapping.

Preventive measures:

1. Strictly control important parameters such as temperature and time of the laminating machine, and regularly conduct crosslinking degree experiments according to requirements, and control the crosslinking degree within 85% ± 5%.

2. Strengthen the improvement and inspection of raw material suppliers.

3. Strengthen the appearance inspection of finished products during the manufacturing process.

4. Strictly control the amount of flux used, and try not to exceed 0.3mm on both sides of the main grid line.

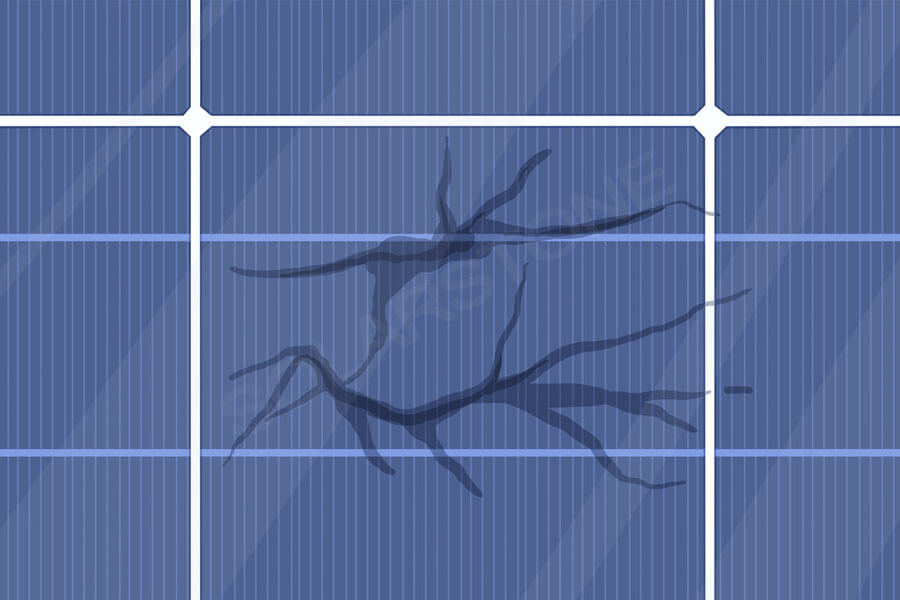

Reasons for delamination and hidden cracks in photovoltaic cells caused by poor silicone

1. Unqualified crosslinking degree (such as low temperature of laminating machine, short lamination time, etc.)

2. Foreign objects on the surface of raw materials such as EVA, glass, and backboard.

3. There are gaps in the border gluing, and after rainwater enters the gaps, the photovoltaic module heats up during long-term operation, resulting in delamination of the photovoltaic module edges.

4. Hidden cracks caused by external forces on photovoltaic cells or modules.

Impact of photovoltaic modules:

1. Layering can cause water to enter the interior of photovoltaic modules, resulting in internal short circuits and scrapping of photovoltaic modules.

2. Cross cracking can cause wrinkles and debris to cause the failure of photovoltaic cells, and the power attenuation of modules directly affects the performance of photovoltaic modules.

Preventive measures:

1. Strictly control important parameters such as temperature and time of the laminating machine, and regularly conduct crosslinking degree experiments according to requirements.

2. Strengthen the improvement and inspection of raw material suppliers.

3. Strengthen the appearance inspection of finished products during the manufacturing process.

4. The final assembly and gluing strictly require operating techniques, and the silicone needs to be completely sealed.

5. Avoid external force collisions when lifting and placing photovoltaic modules.

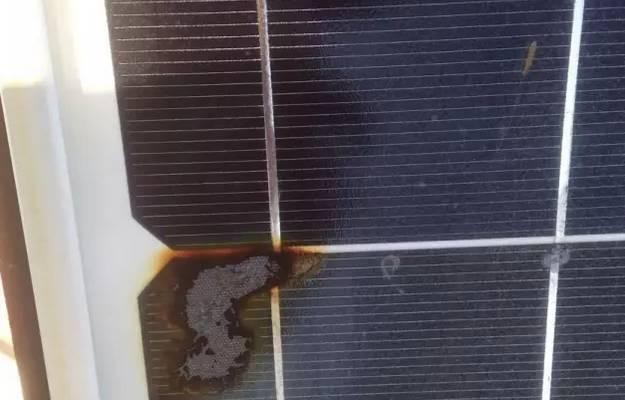

Reason for component burnout

1. The contact area between the busbar and the welding strip is small, or there is an increase in resistance due to poor soldering, resulting in heating and burning of the photovoltaic module.

Impact of photovoltaic modules:

1. There is no impact on photovoltaic modules in a short period of time, and photovoltaic modules working on external power generation systems for a long time will be burned out and eventually scrapped.

Preventive measures:

1. In the welding process of busbar and photovoltaic module repair, it is necessary to strictly follow the requirements of the operation manual for welding to avoid excessively small welding area during the welding process.

2. After welding, it is necessary to visually inspect whether the welding is OK.

3. Strictly control the soldering iron issue within the control range (375 ± 15) and the welding time for 2-3 seconds.

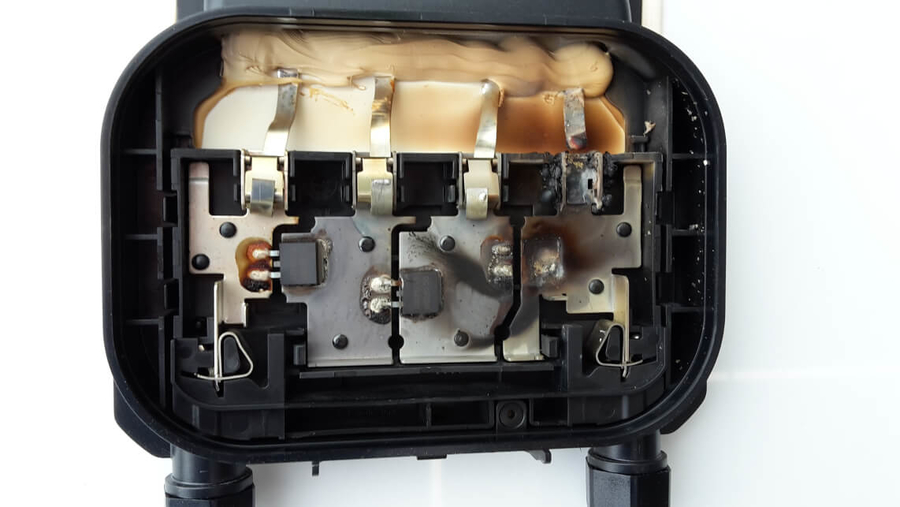

Reason for Fire in Photovoltaic Module Junction Box

1. The lead wire is not tightly clamped in the slot, resulting in a spark.

2. The welding area of the leads and junction boxes is too small, resulting in excessive resistance and causing ignition.

3. If the lead wire is too long and comes into contact with the plastic parts of the junction box, prolonged heating can cause a fire.

Impact of photovoltaic modules:

1. A fire directly causes the scrapping of photovoltaic modules, which may lead to a serious fire

Preventive measures:

1. Strictly follow the SOP operation to fully insert the lead wire into the card slot.

2. The welding area of the lead wire and junction box should be at least greater than 20 square millimeters.

3. Strictly control the length of the outgoing line to meet the drawing requirements and operate according to SOP to avoid contact between the outgoing wires and the plastic parts of the junction box.