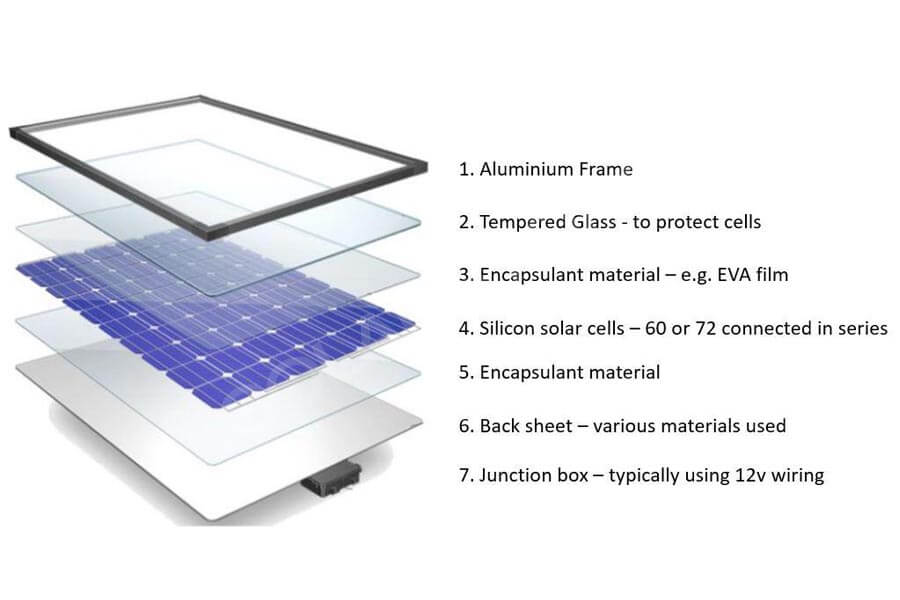

The role of EVA adhesive film in solar panels is to bond tempered glass, solar panels, and back panels together, playing a role in protecting solar panels from water seepage, moisture, and air isolation. Its proportion in the cost of solar panels is usually around 3% -4%.

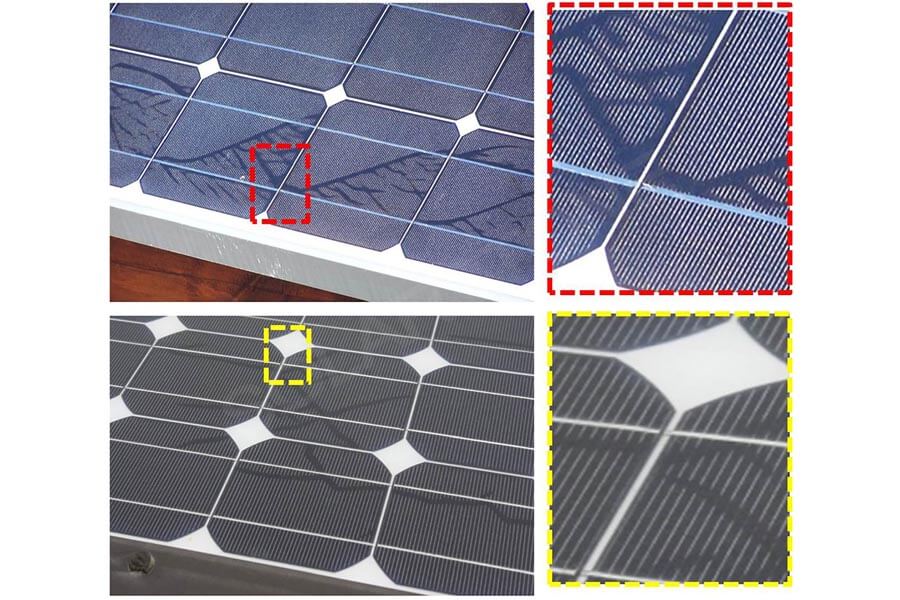

In the application of EVA in photovoltaic products, there is generally a problem of lack of adhesive or insoluble. The reason for the problem may be related to the material. Damping or expiration of EVA materials can also cause EVA to lack adhesive or insoluble;

In work operations, the heating process design of the laminating machine is unreasonable, the lamination temperature is low, and the lamination time is short;

The cross-linking degree experiment failed to identify the correct process parameters of the EVA, and executing incorrect operating instructions can also cause EVA to lack adhesive or not dissolve.

EVA lacks glue or does not dissolve, which can directly affect the production process, affecting process integrity and product yield.

Therefore, once discovered, it is necessary to promptly improve the production process and adjust equipment to ensure normal operation of the process section. The usual measures that can be taken are:

- At the source, select qualified material suppliers, so that the quality inspection technology is excellent and the raw materials are guaranteed to prevent the occurrence of damp or expired EVA raw materials.

- During machine operation, strictly follow the operating requirements and control important parameters such as lamination temperature and lamination time to avoid incorrect instructions and operations.

- Follow the experimental guidelines and specifications, conduct cross-linking degree experiments as required, and control the cross-linking degree within 85% -95%, and maintain the experimental detection level.

- For materials purchased by different manufacturers, different process conditions are used to adjust the parameter indicators of lamination temperature and time, and to change the cross-linking degree experimental detection standards.

By taking the above measures, the probability of EVA lacking glue or not dissolving is reduced, and the error rate is reduced. The non rework of production processes is a strong support and important guarantee for production efficiency.