During the welding process of photovoltaic cells, the issue of welding strip offset cannot be ignored, which is a problem that operators need to pay attention to in their work.

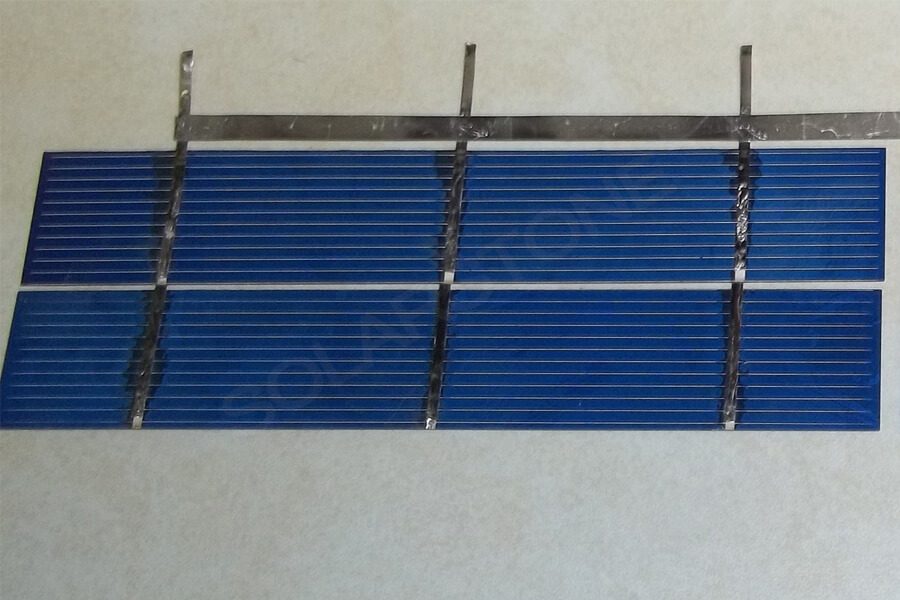

The welding positioning of the interconnection strip must be straight and not bent, otherwise it is easy to cause welding strip offset, and the final welding effect is not ideal.

So, during normal operations, operators must straighten the welding strip before starting welding, ensuring that the welding strip is straight and completely covers the welding printing line of the solar cell, without causing any exposure.

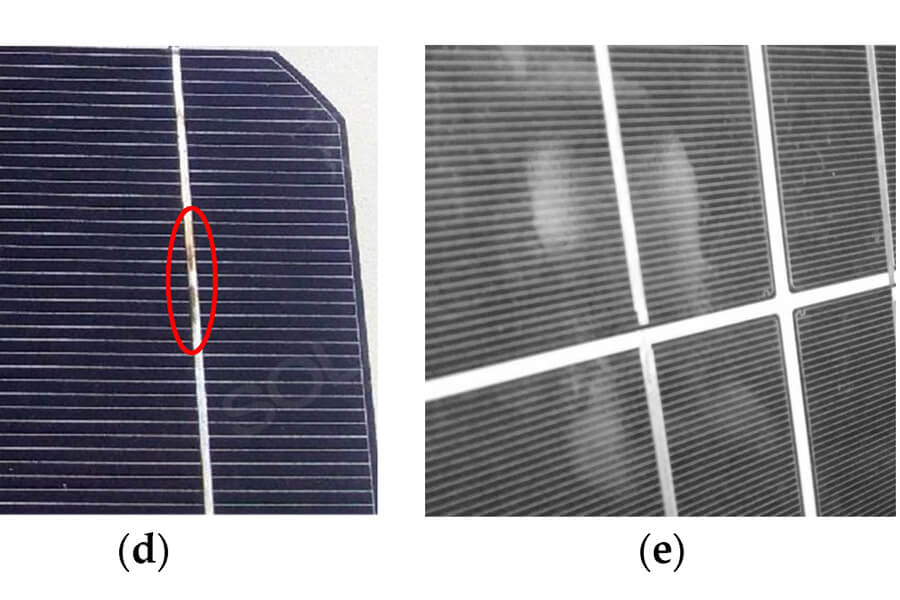

To prevent welding strip deviation (exposure), attention should be paid to:

① Deviation between the positioning of the interconnection strip and the welding printing line position of the solar cell during welding;

② Excessive temperature leads to bending of the welding strip, resulting in bending of the solar cell after welding is completed;

③ During operation, the starting point of the interconnection strip is offset, which can cause welding to be skewed, resulting in bending in the middle or misalignment at both ends.

To effectively prevent welding strip deviation (exposure), measures can be taken to prevent it. To prevent deviation, the position of solar cells on the bottom plate should be fixed;

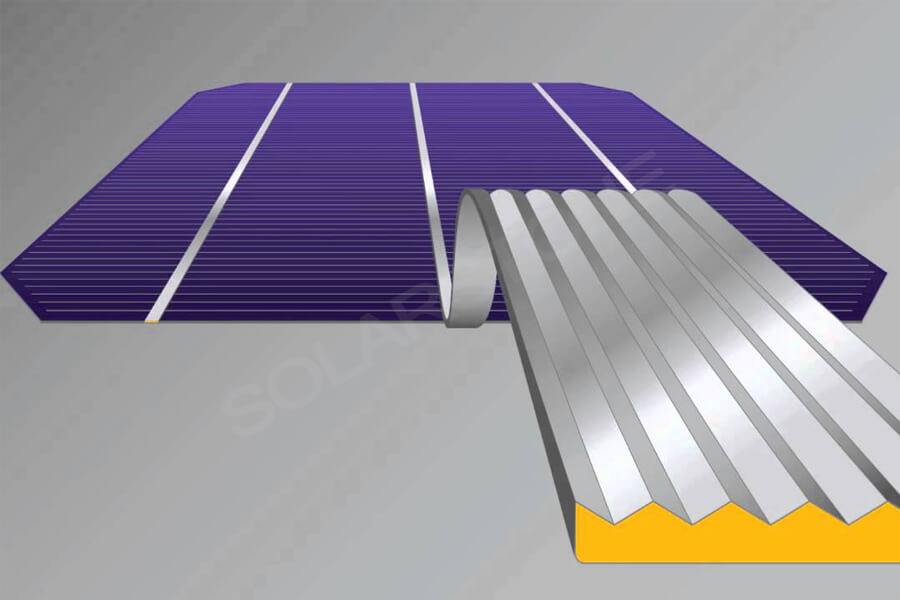

The main grid line of the raw material for solar cells will cause the welding strip to deviate from the main grid line after welding;

During the welding process, it should be kept in mind that interconnecting strips with abnormal deformation of the welding strip cannot be used.

Strictly adhere to operating standards, carry out routine operations according to specified requirements, and carefully identify the selection of interconnection strips.