What is a solar panel?

Solar panel (also called solar module) is the core part of solar power generation system, and also the most important part of solar power generation system.

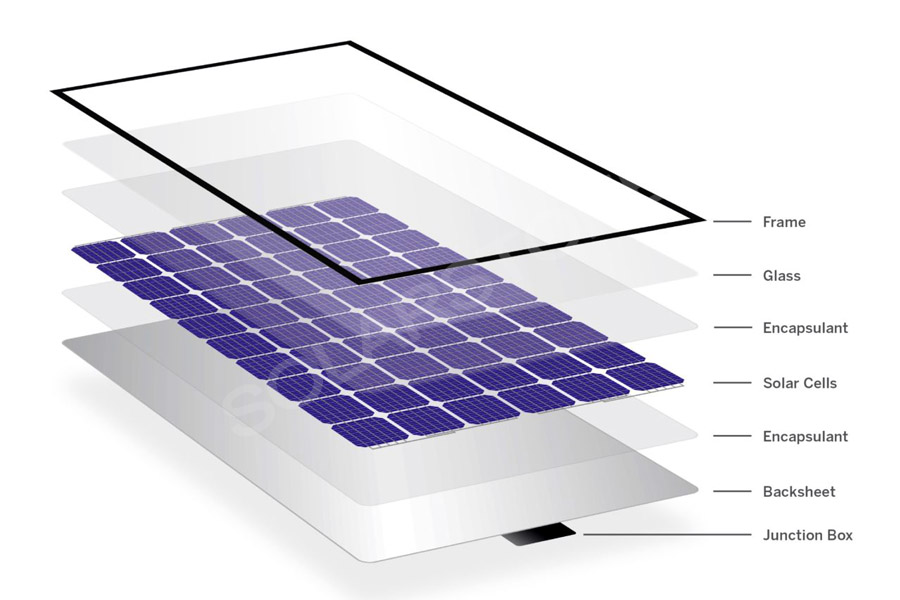

The solar panel is composed of high efficiency single crystal / polycrystalline solar cells, low iron ultra white textured tempered glass, packaging materials (EVA, Poe, etc.), functional backsheet, interconnection bar, bus bar, junction box and aluminum alloy frame. The service life can reach 15-25 years.

Types of solar panels

1.Classification by solar cell material

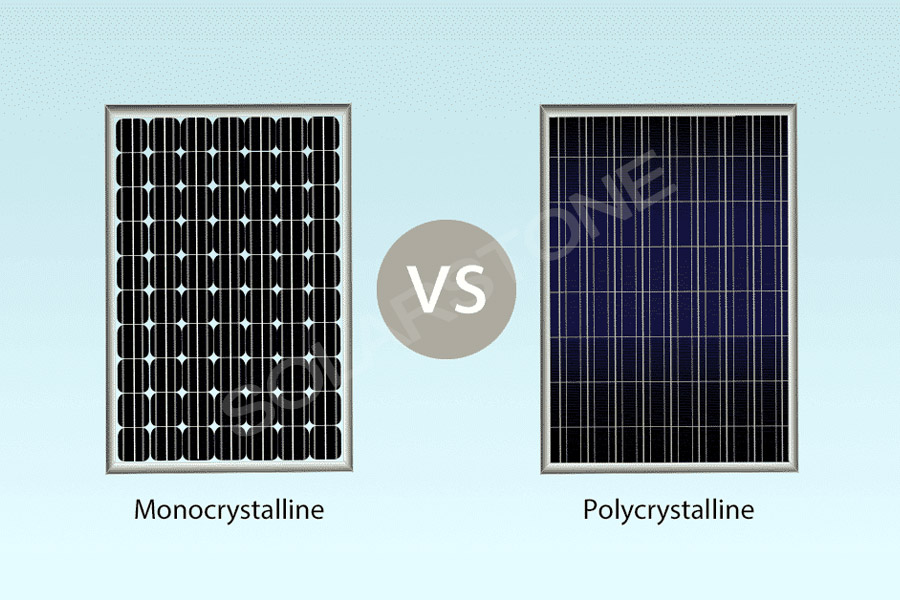

- Monocrystalline silicon solar panels. The photoelectric conversion efficiency of monocrystalline silicon solar panels is about 17%, and the highest is 24%, which is the highest among all kinds of solar panels.

- Polycrystalline silicon solar panels. The fabrication process of polysilicon solar panel is similar to that of monocrystalline silicon solar panel, but the photoelectric conversion efficiency of polysilicon solar panel is much lower. In terms of production cost, it is cheaper than monocrystalline silicon solar panel. The material is easy to manufacture, saving power consumption, and the total production cost is lower. However, the service life of polycrystalline silicon solar panel is shorter than that of monocrystalline silicon solar panel.

- Amorphous silicon solar panels. Amorphous silicon solar panel is a new type of thin-film solar panel which appeared in 1976. It is completely different from monocrystalline silicon and polycrystalline silicon solar panels. The process is greatly simplified. The silicon material consumption is small and the power consumption is lower. Its main advantage is that it can generate electricity under weak light conditions. However, the main problem of amorphous silicon solar panels is that the photoelectric conversion efficiency is low, the international advanced level is about 10%, and it is not stable enough. With the extension of time, the conversion efficiency decays.

2.Classification by production process

- Single layer glass laminated solar panel, which is the most common solar panel on the market, is widely used in civil, industrial, commercial and other fields.

- Double glass laminated solar panels. This is a popular solar panel in recent years, which is used for solar house, building exterior wall, residential roof and so on.

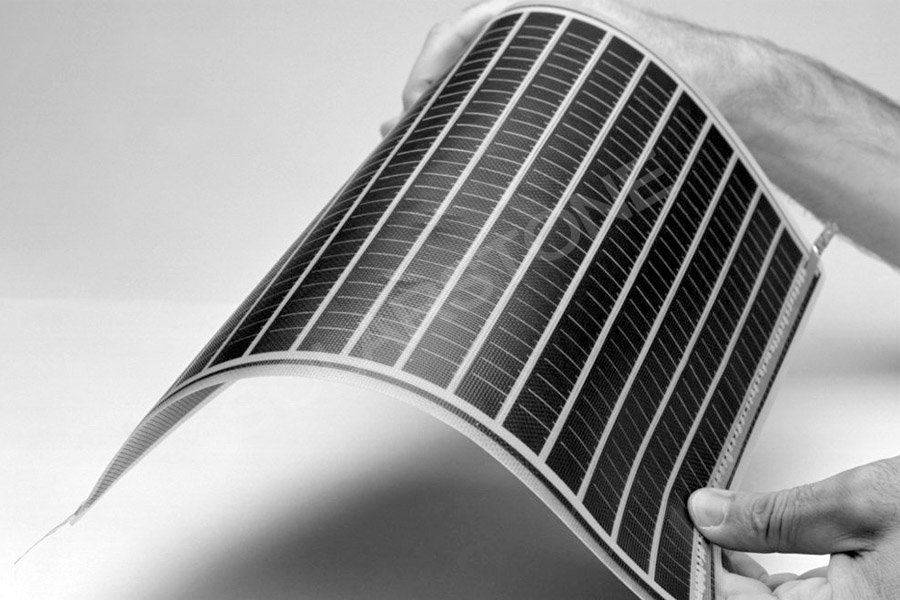

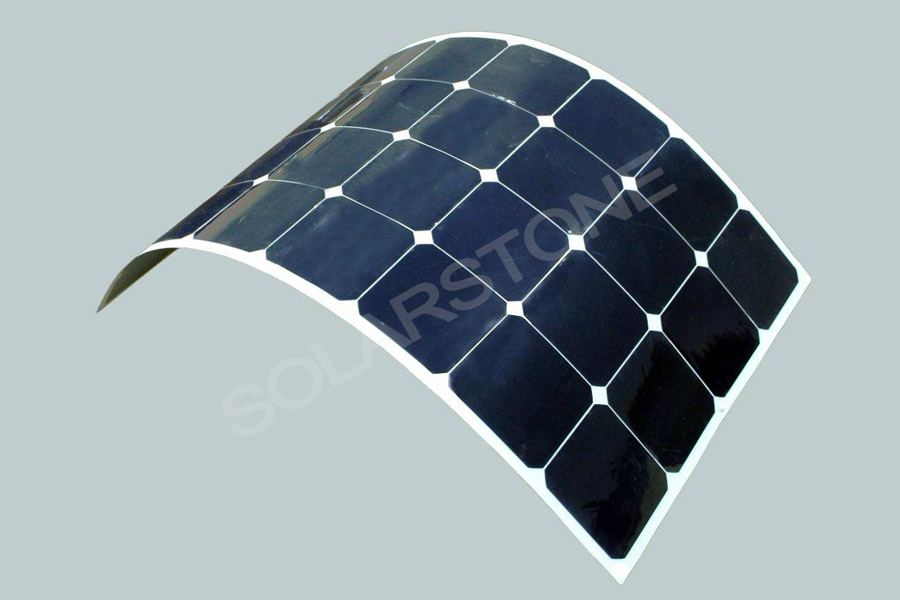

- Flexible solar panels. Flexible solar panel is a new technology product in the world solar industry. It is used on the top of cars, the cabin surface of sailboats, rowing boats and motorboats, and the roof and outer wall of buildings.

- PET laminated solar panels. The solar cells are cut into small pieces by a laser machine and arranged according to the voltage and current required by the customers. Then the single-layer transparent PET, EVA, solar cells, EVA and PCB bottom plates are put into the solar vacuum laminator in order for vacuum lamination. After about 20 minutes, they are taken out and pasted with a soft and transparent film to protect the surface, then a pet laminate solar panel came out. Used for solar lawn lamp, solar wall lamp, solar arts and crafts, solar toys, solar radio, solar flashlight, solar cell phone charger, solar small water pump, solar home / office power supply and portable mobile power system and other products.

- Epoxy laminated solar panel. It is a kind of solar panel, but the packaging method is different. By cutting the solar cell into small pieces, the required voltage and current are made, and then packaged. Because of its small size, it generally does not use the packaging method similar to the solar photovoltaic module, but covers the solar cells with epoxy resin, and is bonded with the PCB circuit board. It has the characteristics of fast production speed, compression and corrosion resistance, beautiful appearance and low cost. Used in solar charger, solar lamp, toy, etc.

Principle of power generation

The energy converter of solar photovoltaic power generation is solar cells, also known as photovoltaic cells. The principle of solar cell power generation is photovoltaic effect. When the sunlight irradiates on the solar cell, the cell absorbs the light energy and produces photogenerated electron hole pairs. Under the action of the built-in electric field, the photogenerated electrons and holes are separated, and the different sign charges accumulate at both ends of the cell, which is called “photovoltage”, which is called “photovoltaic effect”. If the electrodes on both sides of the built-in electric field are led out and connected to the load, the load will have “photo generated current” flowing through, so as to obtain power output. In this way, the light energy of the sun is directly converted into usable electric energy.

Power calculation

Solar AC power generation system is composed of solar panel, charging controller, inverter and battery; Solar DC power generation system does not include inverter. In order to make the solar power generation system to provide enough power for the load, it is necessary to select the components reasonably according to the power of the electrical appliances. Taking 100W output power for 6 hours per day as an example, the following calculation method is introduced:

- First, the watt hours consumed per day (including the loss of the inverter) should be calculated: if the conversion efficiency of the inverter is 90%, then when the output power is 100W, the actual required output power should be 100W / 90% = 111w; If it is used for 5 hours per day, the output power is 111w * 5h = 555wh.

- Calculation of solar panel: the output power of solar panel should be 555wh / 6h / 70% = 130W according to the effective sunshine time of 6 hours per day and considering the charging efficiency and the loss in the charging process. Among them, 70% is the actual use power of solar panels in the charging process.

Technical characteristics and installation requirements

The solar array consists of one or more solar modules. If there is more than one solar module, the current and voltage of the component should be basically the same to reduce the loss of series and parallel combination.

According to the local solar radiation parameters and load characteristics, the total power of solar array is determined; According to the voltage and current requirements of the designed system, the number of solar array series parallel modules is determined.

The solar array bracket is used to support the solar module. The structure design of solar cell array should ensure that the connection between the module and the bracket is firm and reliable, and the solar module can be easily replaced. The solar array and bracket must be able to resist 120 km / h wind without damage.

The bracket can be adjustable or installed at a fixed angle, so that the solar array can obtain the maximum power generation in the design month (that is, the month with the worst average daily radiation).

All fasteners of the square array must have enough strength to fix the solar module on the square array bracket reliably. The solar array can be installed on the roof, but the array bracket must be connected with the main structure of the building, not the roof material.

For the solar array installed on the ground, the minimum distance between the solar module and the ground should be more than 0.3 M. The bottom of the column must be firmly connected to the foundation so that it can bear the weight of the solar array and the design wind speed.

For portable small power supply, the solar panel should be equipped with bracket to make it reliable.

Test method

1. As the output power of solar module depends on solar irradiance, solar cell temperature and other factors, the measurement of solar module is carried out under standard conditions (STC)

Air quality AM1.5, light intensity 1000W / m2, temperature 25 ℃.

2.Open circuit voltage: 500W tungsten halogen lamp, 0 ~ 250V AC transformer, light intensity set at 38000 ~ 40000 lux, distance between lamp and test platform is about 15-20cm, direct test value is open circuit voltage;

3.Under this condition, the maximum output power of the solar module is called the peak power. In many cases, the peak power of the module is usually measured by the solar simulator. The main factors affecting the output performance of solar modules are as follows:

- Load impedance

- Sunshine intensity

- Temperature

- Shadow

What else do you want to know about solar panels? Please send email to sales@solarstonepower.com