Solar panels are designed to have a service life of 25 years, but there are still various problems in the production process that lead to short service life. Here are the 19 most common problems and their analysis, and how to avoid them.

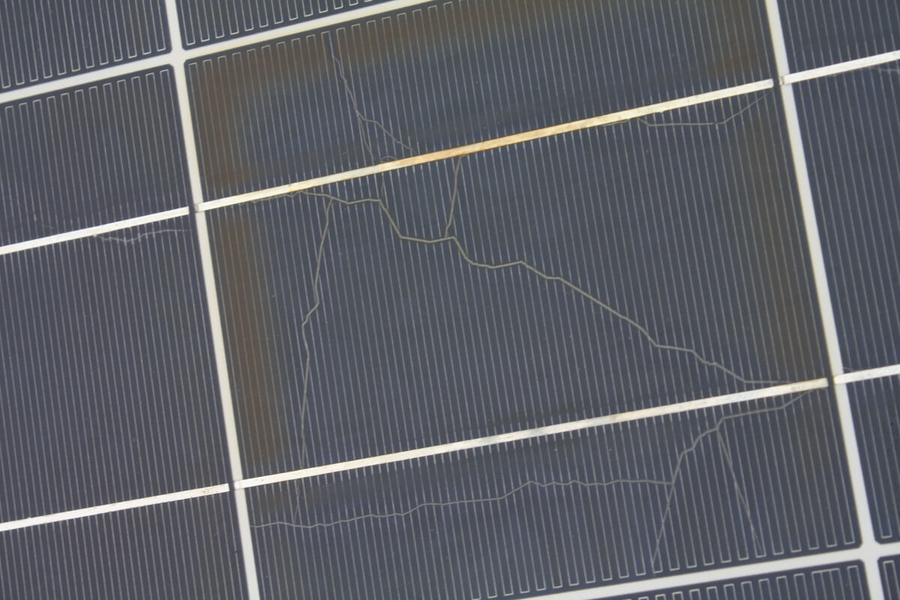

- Reticular crack

Reason:

- The solar cell is impacted by an external force during welding or transportation.

- The solar cell is not preheated at low temperature and suddenly expands after being heated for a short time, resulting in a hidden crack.

Effects on solar panel:

- The network crack will affect the power attenuation of the solar panel.

- Fractures and hot spots appear in the network cracks for a long time, which directly affect the performance of solar panels.

Preventive measures:

- In the production process, avoid the cell from being too impacted by an external force.

- In the welding process, the solar cell should be insulated in advance (hand welding), and the soldering iron temperature should meet the requirements.

- El tests should be strictly inspected.

- EVA delamination

Reason:

- Unqualified crosslinking degree (such as the low temperature of laminating machine and short laminating time).

- There are foreign bodies on the surface of EVA, glass, backsheet, and other raw materials.

- The uneven composition of EVA raw materials (such as ethylene and vinyl acetate) leads to the failure to dissolve at normal temperature, resulting in delamination.

- When the flux is used too much, the main gate line will be delaminated when it is exposed to a high temperature for a long time.

Effects on solar panel:

- The small delamination area affects the high power failure of the solar panel; When the delamination area is large, it will directly lead to the failure and scrapping of the solar panel.

Preventive measures:

- Strictly control the temperature, time, and other important parameters of the laminator, and regularly conduct the crosslinking degree test according to the requirements, and control the crosslinking degree at 85% ± Within 5%.

- Strengthen the improvement of raw material suppliers and raw material inspection.

- Strengthen the appearance inspection of finished products in the process.

- Strictly control the amount of flux, try not to exceed 0.3mm on both sides of the main grid line.

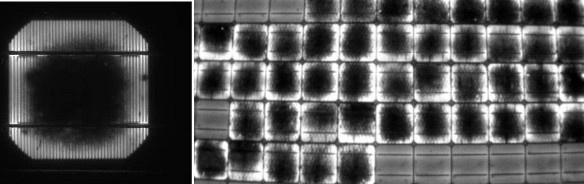

- Delamination caused by poor silica gel & Cross hidden crack of solar cell

Reason:

- Unqualified crosslinking degree (such as the low temperature of laminating machine and short laminating time).

- There are foreign bodies on the surface of EVA, glass, backsheet, and other raw materials.

- There is a gap in the gluing of the frame. After the rainwater enters into the gap, the solar panel heats up during long-time work, resulting in the edge delamination of the solar panel.

- Hidden crack caused by an external force.

Effects on solar panel:

- Delamination will lead to water in the solar panel, short circuits in the solar panel, and scrapping of the solar panel.

- The cross hidden crack will cause the striation fragment to make the solar cell fail, and the power attenuation of the solar panel will directly affect the performance of the solar panel.

Preventive measures:

- Strictly control the temperature, time, and other important parameters of the laminator, and do the crosslinking degree test regularly according to the requirements.

- Strengthen the improvement of raw material suppliers and raw material inspection.

- Strengthen the appearance inspection of finished products in the process.

- The operation method is strictly required for the final assembly, and the silica gel needs to be completely sealed.

- Avoid external force collision when lifting and placing solar panels.

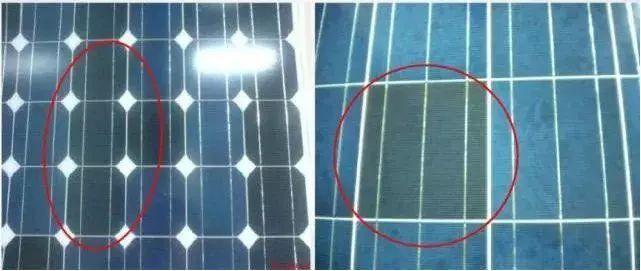

- Solar panel burnt out

Reason:

- The contact area between the bus bar and the welding strip is small or the resistance is increased due to false welding, resulting in heating, resulting in the burnout of the solar panels.

Effects on solar panel:

- It has no effect on the solar panels in a short time, and the solar panels will be burnt out and eventually scrapped if they work on the external power generation system for a long time.

Preventive measures:

- In the process of bus bar welding and solar panel repair, welding shall be carried out in strict accordance with the requirements of the operation instruction to avoid too small a welding area in the welding process.

- After welding, it is necessary to check whether the welding is OK.

- Strictly control the problem of soldering iron within the control range (375 ± 15) And welding time 2-3s.

- Junction box on fire

Reason:

- The lead wire is not clamped tightly in the slot, causing ignition.

- The welding area of the lead wire and junction box is too small and the resistance is too large, causing fire.

- If the lead is too long and contacts the plastic parts of the junction box, the fire will be caused if it is heated for a long time.

Effects on solar panel:

- The fire directly results in the scrapping of solar panels, which may lead to a serious fire.

Preventive measures:

- Insert the outgoing line into the card slot in strict accordance with SOP operation.

- The welding area of the outgoing line and junction box shall be more than 20 square mm at least.

- Strictly control the length of the outgoing line to meet the requirements of the drawing, and operate according to sop to avoid the outgoing line contacting the plastic parts of the junction box.

- Cell crack

Reason:

- Improper operation during welding.

- Improper lifting and placing by personnel.

- Laminator failure.

Effects on solar panel:

- Affects the power attenuation of the solar module.

Preventive measures:

- The welding and rework area of the bus bar shall be operated in strict accordance with the SOP method.

- When personnel lift and place solar panels, they should lift and place solar panels in strict accordance with the process requirements.

- Ensure the regular maintenance of the laminator. Every spare part replacement of the equipment should be done strictly after the first piece is confirmed.

- The El test shall be strictly checked, and the defective leakage shall be prohibited.

- Too much solar cell flux

Reason:

- Excessive flux injection caused by solar cell stringer machine adjustment.

- Too much flux was applied during repair.

Effects on solar panel:

- EVA delamination on the main gate line position of the solar panel.

- After a long time on the power generation system, the solar panels appear lightning black spots, which affect the power attenuation of the solar panels, reduce the service life of the solar panels or cause the solar panels to be scrapped.

Preventive measures:

- Adjust the flux injection amount of the solar cell stringer machine and check regularly.

- In the repair area, please use the designated soldering pen when replacing the solar cell, and it is forbidden to use a big brush to apply the flux.

- False welding and over welding

Reason

- Too much welding temperature or too little or too fast application of flux will lead to false welding.

- Too high welding temperature or too long welding time will lead to over welding.

Effects on solar panel:

- In a short time, the bonding strip and the solar cell strip are delaminating, which affects the power attenuation or failure of the solar panel.

- Over soldering leads to the damage of the inner electrode of the solar cell, which directly affects the power attenuation of the solar panel, reduces the service life of the solar panel, or causes the solar panel to be scrapped.

Preventive measures:

- Ensure the parameter setting of the solar cell stringer machine temperature, flux injection amount, and welding time, and check regularly.

- In the repair area, ensure the temperature and welding time of the soldering iron, and use the correct soldering pen to apply the flux.

- Strengthen the EL inspection to avoid the next process.

- Strip offset or warped fragments after welding

Reason:

- Abnormal positioning of the solar cell stringer machine will cause the deviation of the welding strip.

- The deviation of the main grid line of the raw material will cause the deviation of the welding strip and the main grid line after welding.

- Too high temperature and too high bending hardness of the welding strip lead to the bending of the solar cell after welding.

Effects on solar panel:

- The offset will reduce the contact area between the solder tape and the solar cell, cause delamination or affect the power attenuation.

- Over soldering leads to the damage of the inner electrode of the solar cell, which directly affects the power attenuation of the solar panel, reduces the service life of the solar panel, or causes the solar panel to be scrapped.

- After welding, the solar cell pieces will be broken due to bending.

Preventive measures:

- Regularly check the positioning system of the solar cell stringer machine.

- Strengthen the incoming inspection of the solar cell and the welding strip.

- Tempered glass explosion and junction box wire fracture

Reason:

- The solar panels were seriously impacted by an external force during transportation, resulting in a glass explosion.

- There are impurities in the glass raw material and the raw material self explodes.

- The wire is not placed by the specified position, resulting in the damage of the wire.

Effects on solar panel:

- The glass explosion makes solar panels directly scrapped.

- The damage of the wire leads to the failure of the solar panel power output or the dangerous accident of electric leakage.

Preventive measures:

- The solar panels should be handled with care during lifting to avoid external force collision.

- Strengthen the inspection and test of glass raw materials.

- The wires must be placed in strict accordance with the requirements to avoid being scattered on the solar panels.

- Bubble

Reason:

- If the vacuum time of the laminator press is too short and the temperature is set too low or too high, bubbles will appear.

- If the interior is not clean, foreign matters will appear bubbles.

- Too large or too small size of the upper insulation strip will cause bubbles.

Effects on solar panel:

- The solar panel bubble will affect the delamination, which will lead to scrapping.

Preventive measures:

- The vacuum time and temperature parameters of the laminator press should be set in strict accordance with the process requirements.

- Pay attention to 5S cleaning in the welding and lamination process.

- The cutting size of small insulation strips shall be cut and inspected strictly.

- Low-efficiency solar cells

Reason:

- Mix low-grade solar cells into high-grade solar panels (raw material mixture / or in-process mixture).

Effects on solar panel:

- The overall power of the solar module becomes low, and the power of the solar module decays greatly in a short time.

- The low-efficiency sheet area will generate hot spots and burn the solar panels.

Preventive measures:

- The production line should distinguish different grades of solar cells when putting them into the production line to avoid mixed-use; The solar cell grade in the repair area should also be marked to avoid misuse.

- EL testers should strictly inspect to avoid the leakage of low-efficiency solar cells.

- Silicone bubbles and gaps

Reason:

- The bubbles and gaps of silica gel are mainly caused by the bubbles in the raw material of silica gel or the unstable air pressure of the air gun.

- The main reason for the gap is the nonstandard use of glue by employees.

Effects on solar panel:

- There will be rainwater in places with gaps. After the rainwater enters, when the solar panels are working, they will be heated, which will cause stratification.

Preventive measures:

- Ask the raw material manufacturer to improve and strengthen the IQC inspection.

- The personnel’s gluing technique should be standardized.

- Missing glue

Reason:

- The operator did not work seriously, resulting in missing glue.

- The solar panels of the production line are placed irregularly, and the personnel pulls the wrong products into the next process.

Effects on solar panel:

- If the glue is not applied, rainwater or moisture will enter, causing the fire of solar panels.

Preventive measures:

- Strengthen personnel skills training and enhance self-inspection awareness.

- The production line should be placed in strict accordance with the principle of “3 determinations” to avoid misuse.

- Strictly inspect the solar panels packaging to avoid bad leakage.

- False soldering of lead wire

Reason:

- The personnel’s operation method is not standardized or not serious, resulting in missed welding.

- Soldering iron temperature is too low, too high, or welding time is too short, resulting in false soldering.

Effects on solar panel:

- The power of the solar module is too low.

- The resistance increases due to poor connection, and the solar panels are burned due to ignition.

Preventive measures:

- Strictly require the operators to carry out SOP operations and standardize the operation methods.

- Spot check the temperature of soldering iron on time and standardize the welding time.

- The silica gel of the junction box is not solidified

Reason:

- The ratio of silica gel does not meet the process requirements, resulting in silica gel not curing.

- The glue hole A or B is blocked and the glue does not come out, resulting in non-curing.

Effects on solar panel:

- The silicone non-curing adhesive will flow out from the edge of the gap of the junction box, and the lead wire in the junction box will be exposed to the air. In case of rain or moisture, it will cause power connection and cause the solar panel to catch fire.

Preventive measures:

- Confirm the dry action of silica gel every hour in strict accordance with the regulations.

- Regularly confirm whether the silica gel ratio meets the process requirements.

- The cleaning process should be strictly controlled to ensure 100% curing of silica gel.

- EVA strip turns yellow

Reason:

- EVA strips are exposed to air for a long time, resulting in a mutation.

- The variation of EVA is caused by the contamination of flux and alcohol.

- Chemical reaction with EVA from different manufacturers.

Effects on solar panel:

- Bad appearance is not accepted by customers.

- It may cause delamination.

Preventive measures:

- EVA should be used up within 12 hours in strict accordance with the process requirements after unsealing to avoid long-term exposure to the air.

- Pay attention to the 5S cleaning of the material storage area to avoid contamination during the processing.

- Avoid using EVA with different factories.

- Foreign matter and red pen mark on glass surface

Reason:

- The stack and 5S of the glass feeding place are not clean, causing foreign matters to be pressed in the assembly.

- The personnel marked the defective products, and they forgot to clean up the marks when packaging after the review.

Effects on solar panel:

- Affect the overall appearance of components and cause complaints.

Preventive measures:

- Clean the lamination and glass feeding process for 5S to avoid foreign matters.

- It is forbidden to mark on the solar panel after finding the defect and record the defect position directly on the process card.

- The products of the production line shall be placed in strict accordance with the principle of “3 determinations”.

- Solar panel color difference

Reason:

- The color difference of solar panels is caused by uneven coating during the processing of raw materials.

- The solar cell stringer machine did not put the solar cell according to the color.

- There is no color discrimination confirmation in the repair area, resulting in the color difference of mixed solar cells.

Effects on solar panel:

- Affect the overall appearance of solar panels and cause complaints.

Preventive measures:

- Feedback to raw materials for improvement, and strictly inspect incoming materials.

- The solar cell stringer machine is strictly required to distinguish colors when feeding to avoid mixing.

- Mark the color grade of the solar cells in the repair area to avoid color differences caused by using the wrong solar cell.

If you have any questions about the quality of solar panels, please send an email to sales@solarstonepower.com to get in touch with us, thank you very much.