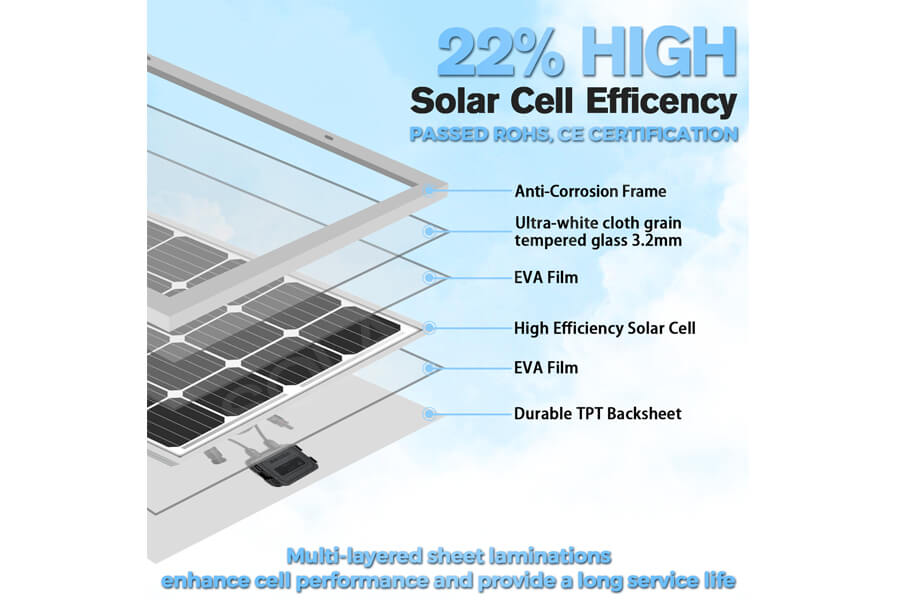

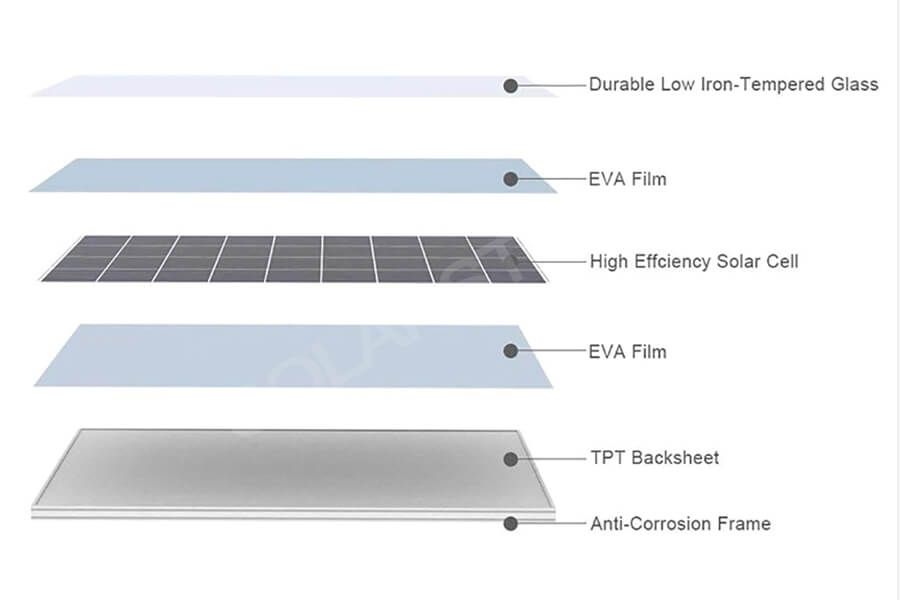

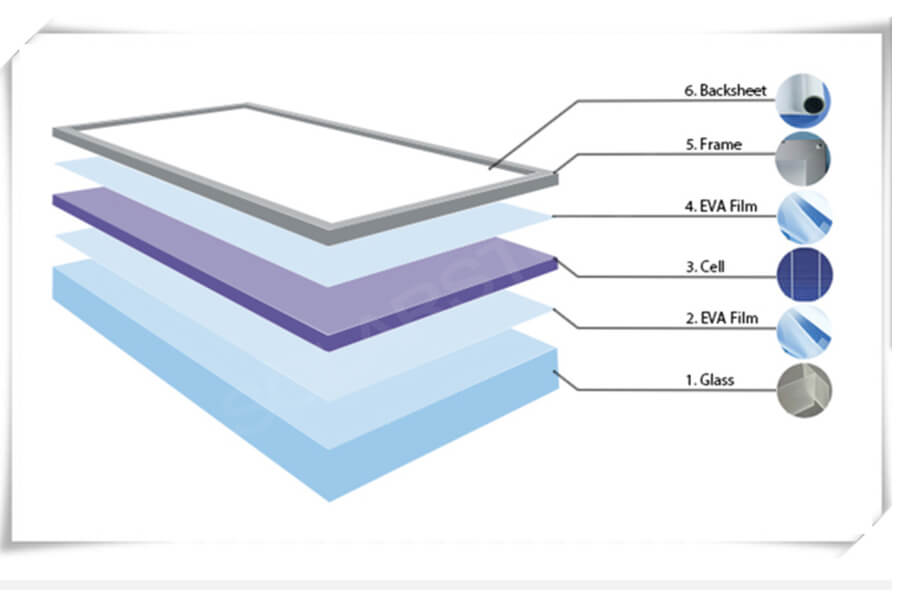

The encapsulation film of solar cells is a key material for packaging photovoltaic modules, which plays a role in packaging and protecting solar cell modules, improving their photoelectric conversion efficiency, and extending their service life.

Due to the irreversibility of the packaging process of photovoltaic modules, coupled with the requirement of a service life of more than 25 years for photovoltaic modules, once the adhesive film of the module begins to turn yellow and crack, the battery is prone to failure and scrapping, which also has a certain impact on the conversion efficiency of the module.

Therefore, although the absolute value of the adhesive film is not high (about 70% to 80% of the production cost of crystalline silicon battery modules comes from the battery cells, and about 3% to 7% comes from the adhesive film and backboard), it plays an important role in the quality and service life of photovoltaic modules, and is the core packaging material of the module, which has high requirements for its performance, quality, and stability.

The development trend of solar cell packaging film industry

The widespread use of renewable energy is a long-term development trend in the future. Although China’s photovoltaic industry has developed into the world’s largest photovoltaic application market, the current energy structure in China is still dominated by traditional energy. Vigorously developing renewable energy and promoting sustainable development is still one of the important development goals of the country.

Solar energy, as an important component of renewable energy, has many advantages and is the main trend for the future development of new energy in China. It is expected that the future development space of China’s solar photovoltaic market is broad.

With the continuous progress of technology and the continuous improvement of product performance, photovoltaic module manufacturers are paying more and more attention to the role of packaging materials in improving power generation efficiency, thus forming a market demand for high-quality adhesive films.

The high functionality requirement of the adhesive film has become a routine requirement

In recent years, the cost of photovoltaic power generation has been continuously decreasing, and the photovoltaic installation market has gradually expanded, forcing the production cost of modules to continue to decline.

At the same time, in order to improve the revenue of power stations and extend their service life, the high functional requirements of photovoltaic film, such as PID resistance, snail pattern resistance, lightning pattern resistance, aging resistance, and water resistance, have become standard performance requirements. The technical and quality requirements for the film are constantly improving.

The demand for white EVA film is rapidly increasing

In order to further improve the power generation of modules, domestic module enterprises have applied white EVA film on the back side of module battery cells to enhance the power generation of modules.

In the current mainstream half panel multi grid components, due to the large battery gaps and the trend of thinness in battery cells, the power improvement effect of white EVA film will be more significant.

At the same time, it can significantly reduce the UV resistance requirements for the inner film of the backboard, further reducing the cost of the component backboard. The demand for white EVA film is rapidly increasing.

The market share of POE adhesive film is expected to further increase

The demand for POE adhesive film has significantly increased, and multi-layer co extruded POE adhesive film has great potential. High efficiency components represented by single crystal PERC double-sided battery modules are developing rapidly, and the demand for corresponding POE adhesive films is significantly increasing.

With the increase in market share of double glass modules and N-type photovoltaic modules, the market share of POE film is also expected to further increase.

Industry integration is accelerating, and market share of advantageous enterprises continues to expand

With industry integration, smaller enterprises are finding it increasingly difficult to maintain high R&D investment and ensure consistency in product quality.

The warranty period of photovoltaic modules is 25 years, and the packaging film plays multiple roles such as light transmission, weather resistance, bonding, PID resistance, buffering, etc. It is the key packaging material that determines the lifespan of the modules.

With the gradual emergence of quality issues in outdoor components in recent years, the problem of small and medium-sized enterprises not valuing quality in the early stage has been exposed, leading to further loss of customer base. The photovoltaic module packaging film industry is accelerating its integration period, and the market share of advantageous enterprises continues to expand.